Knitted Lining Fabric Manufacturers

The company has a high-quality and innovative team. The team members come from different professional backgrounds and have rich industry experience and skilled technical capabilities. They cooperate and make progress together, injecting a steady stream of power into the company's development.

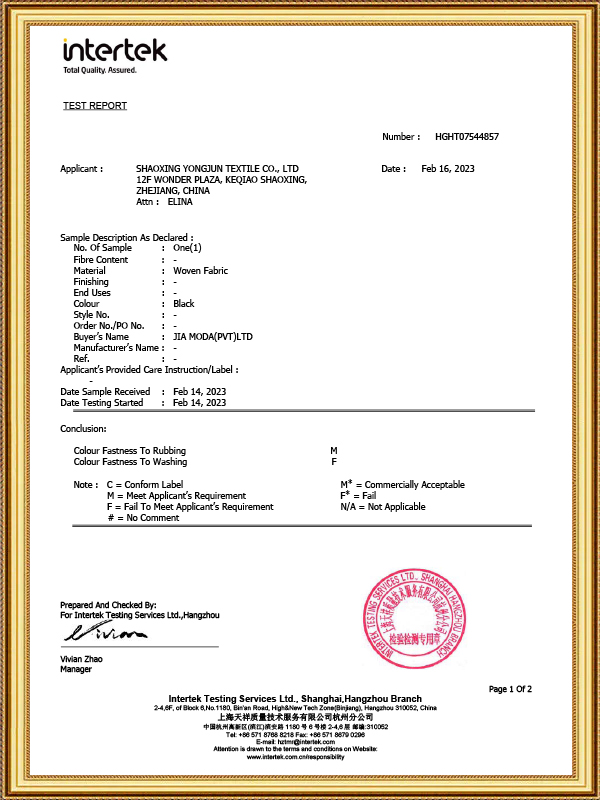

Regarding technology research and development, Yongjun Textile has invested a lot of resources and is constantly pursuing innovation and breakthroughs. The company has advanced R&D facilities and reliable R&D processes, which can quickly respond to market demand and launch competitive products. At present, the company has obtained several patents and technical certifications, and its technical level is at the forefront of the industry.

The company operates professionally in the production and development of linings and women's fabrics, establishing different quality standards to meet customer needs. The "Yongjun" brand was registered in 2006, and the "Jingjun" and "Yuedu" brands were registered in 2018. The company keeps up with customer needs and market trends for research and development, focusing on order-based production. By integrating trade and production through yarn and grey cloth operations, the company ensures that its supply capacity is not constrained.

In terms of quality management, Yongjun Textile has always adhered to strict standards and established a comprehensive quality management system. From raw material procurement to production and processing, to product testing and after-sales service, every link is strictly controlled to ensure the stability and reliability of product quality.

In addition to achieving remarkable results in the domestic market, the products have spread to over 60 countries and regions worldwide, including the United States, the European Union, the United Kingdom, Eastern Europe (Russia, Belarus, Poland, Ukraine, Kazakhstan, Kyrgyzstan, Tajikistan, etc.), Canada, South America (Brazil, Argentina, Chile, Bolivia, Colombia, Panama, Mexico, etc.), South Africa, North Africa (Egypt, Tunisia, Morocco, etc.), the Middle East (Saudi Arabia, UAE, Iran, Lebanon, Israel, etc.), Southeast Asia (Thailand, Malaysia, Indonesia, Singapore, Vietnam, etc.), and Asia (India, Nepal, Japan, South Korea, etc.). A strong brand image has been established in international markets.

As a socially responsible enterprise, we base our judgment on altruism, always striving for the material and spiritual well-being of all employees and contributing to the development of society.

In the brand development plan for the next 3-5 years, "Yongjun Lining" will improve the quality of high-end products, meet the functional needs of consumers, enhance brand awareness, and develop more international customers. "Jingjun Lady Fabrics" will quickly and accurately develop new products to meet the requirements of domestic and foreign brands, speed up delivery in the e-commerce market, improve product quality and brand recognition, and develop international customers. "Yuedu" scarves will strengthen design and development over the next three years to support clothing coordination. Additionally, the company will increase the learning efforts of the R&D and sales teams in textile professionalism, improve the level of digital management, and apply technological management tools. In 2024, the company plans to establish a production base in another province, with the first phase of weaving, printing, and dyeing production, and support new product development through comprehensive testing. The company is committed to solving clothing problems for consumers, producing high-quality and reasonably priced products, promoting the market towards health, and enhancing the independent innovation capabilities of Chinese companies.

-

Shaoxing Yongjun Textile 2026: Kick-off • Learning • Hiking • Blessing

Crack the whip and gallop toward a new journey! Shaoxing Yongjun Textile 2026 Grand Opening! On February 24, 2026 (the 8th day of the first month in...

READ MORE -

Does textured satin fabric support environmentally friendly recycled fibers?

Understanding the Composition of Textured Satin Fabric Textured satin fabric is characterized by its smooth surface sheen combined with a subtle three...

READ MORE -

Is the jacquard pattern of the dobby striped lining uniform, durable, and resistant to wear and fading?

Overview of Dobby Striped Lining and Jacquard Patterns Dobby striped lining is a type of fabric commonly used in garments, accessories, and interior a...

READ MORE -

Has the polyester twill lining been treated for anti-static, moisture-wicking, or wrinkle resistance?

Overview of Polyester Twill Lining and Its Functional Treatments Polyester twill lining is widely used in garments, industrial applications, and uphol...

READ MORE -

Is the antibacterial, odor-resistant, and anti-pilling treatment of the polyester textile fabric stable?

Understanding Functional Finishes on Polyester Textile Fabric Polyester textile fabric is widely used in apparel, home textiles, bags, footwear, and i...

READ MORE -

Shaoxing Yongjun Textile Co., Ltd. Successfully Concludes Participation at Texworld Apparel Sourcing Paris 2026

Shaoxing Yongjun Textile Co., Ltd. successfully concluded its participation in Texworld Apparel Sourcing Paris 2026, held from February 2 to 4, 2026, ...

READ MORE

In the modern apparel and home textile industry, knitted fabrics are highly favored for their softness, comfort, and excellent elasticity. Among them, cotton jersey fabric and polyester-cotton blended jersey fabric are the most widely used products in the market. Although they may look similar in appearance, there are significant differences in moisture absorption, breathability, comfort, and wearing experience. Shaoxing Yongjun Textile Co.,Ltd., as a professional enterprise engaged in the research, development, and production of knitted and woven linings, has accumulated rich experience in this field over the years and can provide customers with high-quality and performance-excellent fabric products.

Firstly, in terms of raw material properties, cotton jersey fabric is made of natural cotton fibers, offering excellent skin-friendliness and breathability. The porous structure of cotton fibers allows for rapid absorption and release of moisture, keeping the wearer dry even in hot or humid conditions. In contrast, polyester-cotton blended fabrics contain a certain proportion of polyester fibers, which, although enhancing the fabric's strength and abrasion resistance, are synthetic fibers with far lower moisture absorption compared to pure cotton. As a result, in high-temperature or high-humidity conditions, polyester-cotton blended fabrics release sweat more slowly, leading to reduced wearing comfort.

Secondly, regarding breathability, the arrangement of cotton fibers and the knitted structure work together to allow air to flow freely between the fibers, improving the overall breathability of the fabric. Shaoxing Yongjun Textile Co.,Ltd., through years of technical accumulation, can adjust knitting density and yarn composition according to customer requirements, ensuring that cotton jersey fabric maintains softness while providing breathable and lightweight wearing experience. In contrast, polyester-cotton blended fabrics, due to the presence of synthetic fibers, have relatively lower pore rates for air circulation, and even after finishing processes, they cannot fully match the breathability of pure cotton jersey fabrics.

From the perspective of comfort, pure cotton jersey fabrics are naturally soft and skin-friendly, with a delicate touch that does not irritate the skin, making them ideal for garments in direct contact with the skin, such as T-shirts, underwear, and loungewear. Shaoxing Yongjun Textile Co.,Ltd. strictly controls yarn precision and knitting uniformity during production to ensure cotton jersey fabrics are soft and drape well, and further enhances wearing comfort through appropriate finishing processes, such as softening or slight napping. By comparison, polyester-cotton blended fabrics, although advantageous in durability and wrinkle resistance, have relatively stiffer hand-feel, and prolonged wear may feel slightly less breathable and warmer, especially in hot or active scenarios.

In addition, the superior moisture absorption and sweat-wicking properties of cotton jersey fabric provide wider application potential in functional apparel. Shaoxing Yongjun Textile Co.,Ltd., leveraging its advanced R&D capabilities, can develop diversified cotton jersey fabrics tailored to different applications, adjusting yarn ratios and knitting density to meet the breathability needs of high-end T-shirts and sportswear while also catering to warmth requirements in autumn and winter. Although polyester-cotton blended fabrics are easy to process and dye with high yield, their moisture absorption and breathability under extreme conditions still fall short of pure cotton jersey, which is why many high-end apparel brands prefer pure cotton in fabric selection.

Since its establishment in 2003, Shaoxing Yongjun Textile Co.,Ltd. has focused on the research, development, and production of high-quality linings and knitted fabrics, accumulating extensive experience in cotton jersey production and advanced process control systems. From raw material procurement to dyeing and finishing, and from yarn selection to knitting structure design, every step is strictly controlled to ensure that each meter of cotton jersey fabric balances moisture absorption, breathability, and comfort. The company also offers various polyester-cotton blended fabrics to balance durability, color fastness, and cost control, but pure cotton jersey fabrics maintain obvious advantages in comfort and breathability.

Shaoxing Yongjun Textile Co.,Ltd., through years of technical accumulation and R&D innovation, is capable of providing global customers with cotton jersey fabrics of superior performance and stable quality, helping apparel enterprises enhance product comfort and market competitiveness. Whether for functional clothing, loungewear, or high-end custom apparel, selecting a professional and reliable cotton jersey fabric supplier is key to ensuring garment quality and user experience.

Cotton jersey fabric, with its natural softness, breathability, and comfort, has become a preferred material in modern apparel and functional fabrics. To meet various design needs and enhance fabric added value, surface finishing techniques such as embossing, printing, and hot stamping are widely applied. However, while enhancing visual effects and design, these techniques also pose technical challenges to the fabric's moisture absorption, breathability, and comfort. Shaoxing Yongjun Textile Co.,Ltd., as a professional enterprise engaged in knitted and woven linings production, has accumulated extensive experience in these processes over the years and can optimize fabric functionality while ensuring aesthetic results, meeting the high-quality demands of global customers.

Firstly, embossing involves imprinting patterns onto the cotton jersey fabric surface under high temperature and pressure, creating three-dimensional textures and rich tactile effects. For cotton jersey, embossing is suitable for high-end T-shirts, loungewear, and children’s clothing requiring intricate designs. Shaoxing Yongjun Textile Co.,Ltd. applies scientifically controlled temperature and pressure parameters during embossing to prevent fiber structure damage and minimize negative impacts on moisture absorption and breathability. Over-embossing may increase fiber density, slightly reducing breathability; therefore, pattern design should balance visual appeal and fabric functionality to ensure comfort.

Secondly, printing involves transferring pigments or dyes directly onto the cotton jersey surface to form patterns. Printing offers advantages of vibrant colors and clear patterns, enabling diverse creative designs. In practice, Shaoxing Yongjun Textile Co.,Ltd. uses eco-friendly water-based or reactive dyes for printing, ensuring colorfastness while minimizing interference with the cotton fibers’ moisture absorption. Compared to coating-based prints, reactive printing bonds closely with fibers without forming thick layers on the surface, thus having minimal impact on breathability and softness. However, large print areas or multi-layer patterns require careful control of print thickness to avoid localized “stuffiness” or stiffness, maintaining the fabric’s original comfort.

Hot stamping, on the other hand, applies metallic foils or powders to the fabric surface under high temperature to achieve shiny, luxurious decorative effects. The key to hot stamping lies in temperature and pressure control. Shaoxing Yongjun Textile Co.,Ltd. employs advanced hot stamping equipment and precise process parameters to ensure clear, durable patterns while protecting fabric softness. Notably, the hot stamping layer itself does not absorb moisture and may slightly reduce breathability locally; hence, large-area designs should consider knitting structure and fabric thickness for optimal pattern distribution, ensuring overall wearing comfort.

From the perspective of moisture absorption, breathability, and comfort, embossing and reactive printing have relatively minor effects on cotton jersey breathability, while hot stamping may slightly reduce breathability locally. Through optimized processes, Shaoxing Yongjun Textile Co.,Ltd. ensures that overall fabric breathability, softness, and skin-friendly comfort are not significantly compromised. Furthermore, the company can customize fabrics according to customer needs, considering knitting density, yarn thickness, and finishing techniques (e.g., softening or slight napping) to achieve an optimal balance between aesthetics and functionality.

Since its establishment in 2003, Shaoxing Yongjun Textile Co.,Ltd. has focused on high-quality knitted and woven linings, accumulating rich experience and technical strength. The company possesses independent R&D capabilities and multiple patents in embossing, printing, and hot stamping processes. With strict production management and quality control systems, each meter of cotton jersey fabric is ensured to achieve excellent visual effect while maintaining moisture absorption, breathability, and comfort. Whether for high-end apparel, functional clothing, or loungewear, selecting cotton jersey fabric from Shaoxing Yongjun Textile Co.,Ltd. provides customers with safe, durable, and aesthetically rich products.

Embossing, printing, and hot stamping techniques are broadly applicable to cotton jersey fabrics, but process design and operation need to consider impacts on moisture absorption, breathability, and softness. Shaoxing Yongjun Textile Co.,Ltd., with advanced process control and rich production experience, can provide cotton jersey fabrics that combine aesthetics, comfort, and functionality, enhancing product added value and wearing experience for apparel brands.

Cotton jersey fabric, with its soft, skin-friendly, breathable, and moderately elastic properties, is widely used in modern apparel. Depending on garment type, the design and processing priorities of cotton jersey vary for T-shirts, sportswear, and loungewear. Shaoxing Yongjun Textile Co.,Ltd., as a professional enterprise engaged in knitted and woven linings R&D and production since 2003, has continuously focused on high-quality fabric development and innovation, providing global customers with diversified and functional cotton jersey products.

Firstly, in T-shirt applications, cotton jersey fabric prioritizes lightness, softness, and breathability. T-shirts are close-fitting garments worn directly on the skin, requiring high comfort. Shaoxing Yongjun Textile Co.,Ltd. selects combed cotton or long-staple cotton yarn for T-shirt fabrics, ensuring smooth surface and delicate hand-feel, while optimizing knitting density and yarn ratio to maintain lightweight breathability. These fabrics exhibit excellent moisture absorption, quickly absorbing and releasing sweat to keep the wearer dry during daily or light activities. In addition, the company applies eco-friendly reactive dyes and softening finishing techniques to ensure vibrant colors and lasting softness, meeting the quality standards of mid-to-high-end T-shirt markets.

In sportswear applications, cotton jersey fabric emphasizes elasticity, abrasion resistance, and sweat-wicking performance. Sportswear involves high-intensity movement, so fabrics must be soft and skin-friendly while maintaining shape and functional performance. Shaoxing Yongjun Textile Co.,Ltd. blends appropriate amounts of polyester fibers or incorporates ribbed or double-sided knitting structures in pure cotton fabrics to enhance resilience and abrasion resistance, while optimizing knitting density for better breathability. These fabrics offer excellent sweat-wicking, tensile strength, and durability, meeting the dual demands of comfort and functionality in sportswear. Additionally, localized functional treatments, such as quick-dry finishing or micro-elastic processing, can be applied to keep the wearer dry and comfortable during prolonged activity.

For loungewear, cotton jersey fabrics focus more on softness and warmth. Loungewear emphasizes long-term close contact with the skin, making comfort and skin-friendliness the core requirements. Shaoxing Yongjun Textile Co.,Ltd. uses higher-count pure cotton yarns for loungewear and applies napping or brushing processes to enhance softness and warmth, providing a fuller hand-feel while maintaining breathability and moisture absorption to ensure comfort without overheating. The company can adjust fabric thickness and knitting structure according to seasonal changes, offering tailored solutions for spring/summer and autumn/winter loungewear, balancing comfort and practicality.

Shaoxing Yongjun Textile Co.,Ltd. consistently integrates garment application scenarios into fabric R&D and production for customized design. T-shirt fabrics emphasize lightweight breathability, sportswear fabrics prioritize elasticity and functionality, and loungewear fabrics focus on softness and warmth. By scientifically selecting yarn materials, knitting structures, and finishing techniques, the company fully leverages cotton jersey’s natural advantages to provide high-quality fabrics suitable for different applications. With advanced R&D facilities and strict quality management, each batch of fabric achieves reliable standards in comfort, moisture absorption, breathability, and durability.

Shaoxing Yongjun Textile Co.,Ltd.’s cotton jersey fabrics are exported to more than 60 countries and regions worldwide, including Europe, North America, Eastern Europe, South America, and Asia, gaining high recognition for quality and functionality. Whether used for daily T-shirts, professional sportswear, or loungewear, the company provides customized solutions that meet diverse customer needs while balancing aesthetics, comfort, and durability, effectively enhancing brand competitiveness.

English

English 中文简体

中文简体