Overview of Polyester Twill Lining and Its Functional Treatments

Polyester twill lining is widely used in garments, industrial applications, and upholstery due to its durability, smooth texture, and ease of handling. The fabric is characterized by its diagonal weave pattern, which provides strength and flexibility. Beyond the basic material properties, polyester twill fabric can undergo various treatments to enhance performance. Anti-static, moisture-wicking, and wrinkle resistance are among the most common functional treatments applied to polyester twill lining to improve comfort, usability, and maintenance.

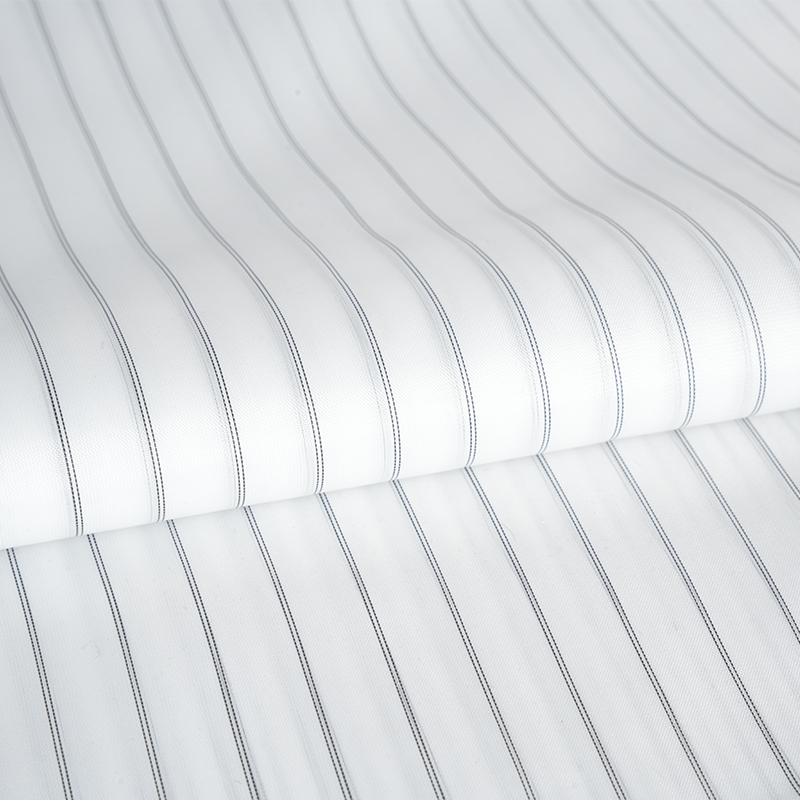

Structure and Properties of Polyester Twill Fabric

Polyester twill fabric is constructed using a twill weave, which produces diagonal ribs on the surface. This weave structure increases the fabric's tensile strength and abrasion resistance compared to plain weaves. Polyester fibers themselves are inherently hydrophobic and resistant to shrinkage, which contributes to durability. However, to achieve specific functional properties such as anti-static, moisture-wicking, or wrinkle resistance, additional chemical or mechanical treatments are often applied to the polyester twill lining.

Anti-Static Treatment

Anti-static treatments are designed to reduce the buildup of static electricity on polyester twill fabric. This is particularly important in garments, industrial clothing, and electronic-sensitive environments. Treatments involve applying conductive finishes or surface coatings that allow static charges to dissipate. Polyester twill lining with anti-static properties minimizes clinging, sparks, and dust attraction, enhancing comfort and safety. The effectiveness of anti-static treatment depends on the type of finish, the application method, and environmental conditions such as humidity.

Moisture-Wicking Treatment

Moisture-wicking treatment enhances the ability of polyester twill lining to draw sweat or moisture away from the body surface, promoting evaporation and comfort. This treatment typically uses hydrophilic finishes or fiber modification techniques to improve the capillary action of the fabric. Polyester twill fabric treated for moisture management can help regulate temperature in garments, reduce discomfort from wetness, and maintain a dry feel. The performance of moisture-wicking treatment can be affected by the thickness of the fabric, the density of the weave, and repeated laundering.

Wrinkle-Resistant Treatment

Wrinkle resistance is achieved through chemical finishes or heat-setting processes that stabilize the polyester twill fabric structure. Wrinkle-resistant polyester twill lining retains smoothness after folding, storage, or wear, reducing the need for ironing and enhancing the appearance of garments or products. Treatments often involve cross-linking agents that maintain fiber alignment and surface tension, allowing the fabric to recover from creases more readily. The longevity of wrinkle resistance depends on the durability of the treatment and the care of the fabric.

| Treatment Type | Purpose | Application Method | Expected Effect on Polyester Twill Lining |

| Anti-static | Reduce static electricity buildup | Conductive finishes or surface coatings | Minimizes clinging, dust attraction, and sparks |

| Moisture-wicking | Draw moisture away from surface | Hydrophilic finishes, fiber modification | Improves comfort and evaporation, keeps fabric dry |

| Wrinkle-resistant | Maintain smooth appearance | Chemical cross-linking, heat-setting | Reduces creasing, simplifies care and handling |

Interrelationship of Functional Treatments

Anti-static, moisture-wicking, and wrinkle-resistant treatments can be applied independently or in combination. Polyester twill lining that receives multiple treatments must maintain fiber integrity and surface characteristics. Some treatments may interact, requiring careful formulation to avoid adverse effects. For example, certain hydrophilic finishes for moisture-wicking may influence the performance of anti-static treatments. Optimized application methods allow polyester twill fabric to achieve multiple functional properties without compromising durability or aesthetics.

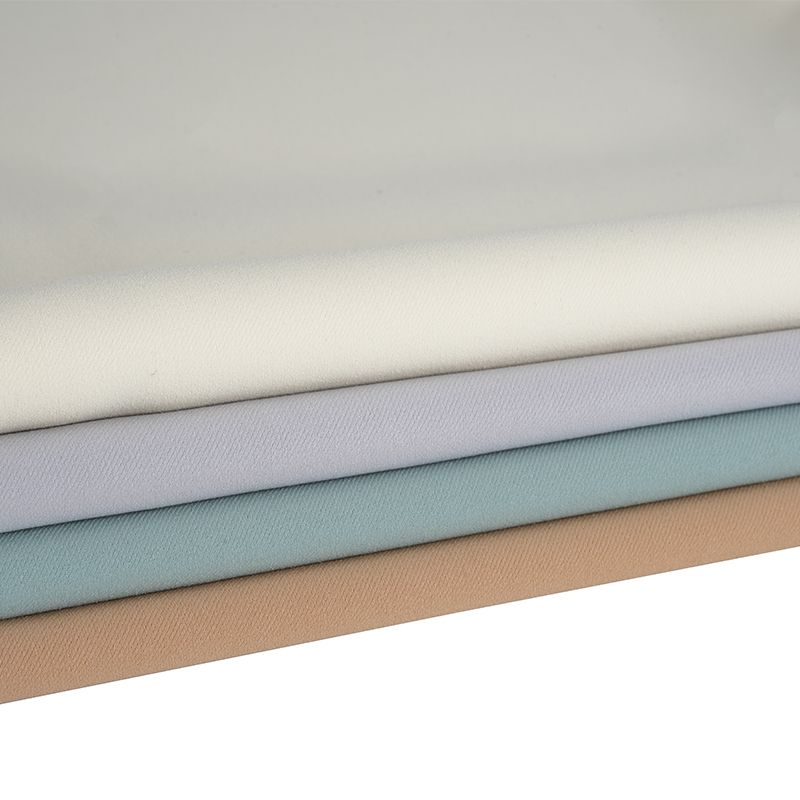

Effect on Fabric Hand and Appearance

Functional treatments can affect the tactile feel, drape, and appearance of polyester twill lining. Anti-static treatments are typically lightweight and do not noticeably alter fabric hand. Moisture-wicking finishes may slightly increase surface smoothness, while wrinkle-resistant treatments can slightly stiffen the fabric depending on the cross-linking degree. The selection and application of treatments aim to balance functionality with the natural softness and flexibility of polyester twill fabric, ensuring comfort and usability in end products.

Durability of Functional Treatments

The long-term performance of anti-static, moisture-wicking, and wrinkle-resistant treatments depends on laundering, exposure to heat, and abrasion. Durable finishes are designed to withstand repeated washing cycles while retaining effectiveness. Polyester twill lining that has undergone high-quality treatment maintains anti-static behavior, moisture management, and wrinkle resistance over extended use. However, certain mechanical stresses or harsh cleaning conditions can reduce treatment efficacy over time, highlighting the need for appropriate care instructions.

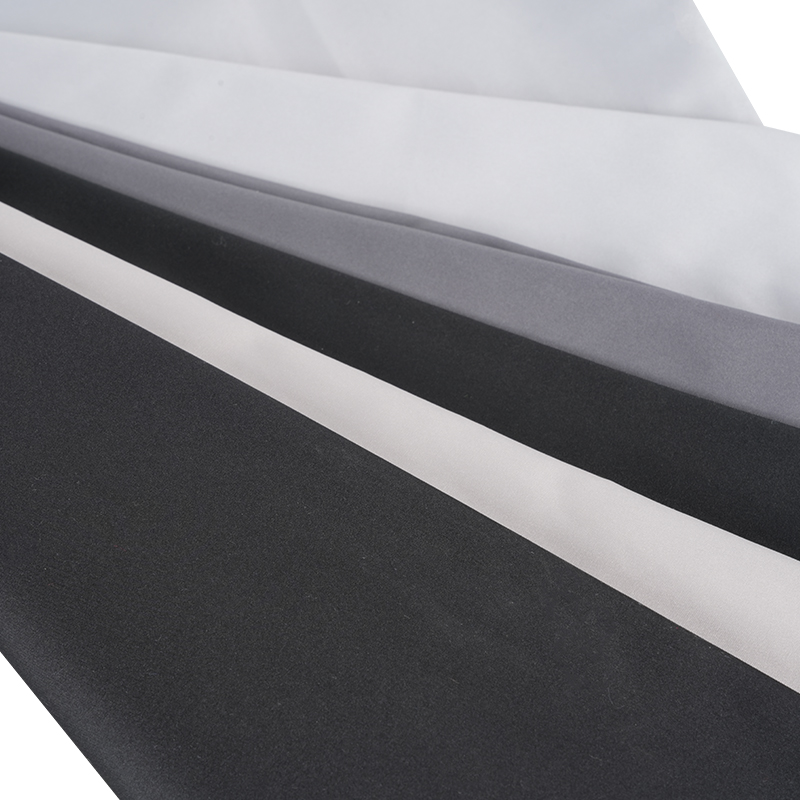

Applications in Garments and Industrial Products

Polyester twill lining with these functional properties is used in a wide range of applications, including jackets, coats, uniforms, protective clothing, and upholstery. Anti-static properties are particularly valued in cleanroom garments and electronics-related industries. Moisture-wicking treatments enhance comfort in activewear and sports garments, while wrinkle resistance improves appearance and reduces maintenance in office wear and travel clothing. Each application benefits from a combination of the fabric’s inherent properties and the added functional treatments.

Influence of Fabric Weight and Weave Density

The effectiveness of treatments in polyester twill lining is influenced by fabric weight, thickness, and weave density. Heavier fabrics with dense twill weaves may require more robust application of moisture-wicking finishes to maintain effective capillary action. Similarly, anti-static finishes may be more effective on lighter fabrics where static buildup is more pronounced. Understanding the interplay between fabric structure and treatment performance helps optimize functional properties for specific end uses.

Environmental and Care Considerations

The performance of treated polyester twill fabric can be influenced by environmental factors such as humidity, temperature, and exposure to contaminants. Anti-static treatments are more effective in dry conditions, while moisture-wicking finishes function optimally when airflow allows evaporation. Wrinkle-resistant properties can be affected by excessive heat or harsh mechanical handling. Proper care, including adherence to recommended washing and drying conditions, helps preserve the functional performance of polyester twill lining over time.

Inspection and Quality Assurance

Quality control during production ensures that polyester twill fabric achieves intended functional properties. Tests may include measuring static dissipation, moisture absorption and release rates, and wrinkle recovery after folding or compression. Polyester twill lining that passes these tests provides reliable performance in the final product. Consistent manufacturing processes and inspection procedures help maintain treatment uniformity across large production batches, ensuring end-user satisfaction and functional reliability.

Integration of Treatments in Product Design

When incorporating polyester twill lining into garments or industrial products, designers consider the combination of anti-static, moisture-wicking, and wrinkle-resistant properties. The selection of treatments is guided by the intended environment, frequency of use, and comfort requirements. Integrating these treatments allows polyester twill fabric to enhance both performance and user experience, offering fabrics that are practical, comfortable, and low-maintenance across a range of applications.

Field Performance and User Experience

Practical use of polyester twill lining with anti-static, moisture-wicking, and wrinkle-resistant treatments demonstrates consistent performance in real-world conditions. Users experience reduced clinging, improved moisture management, and easier garment maintenance. Industrial applications benefit from safer handling in static-sensitive environments, while garments maintain a neat appearance with less frequent ironing. These functional treatments contribute to both the practical and aesthetic qualities of polyester twill fabric, extending the usability and satisfaction of the final product.

English

English 中文简体

中文简体