Understanding Functional Finishes on Polyester Textile Fabric

Polyester textile fabric is widely used in apparel, home textiles, bags, footwear, and industrial products because of its balanced mechanical properties and processing flexibility. To meet higher usage expectations, functional treatments such as antibacterial, odor-resistant, and anti-pilling finishes are often applied. The stability of these treatments determines whether the fabric can maintain performance after repeated washing, friction, heat exposure, and long-term use.

Mechanisms Behind Antibacterial Treatments

Antibacterial finishes on polyester textile fabric generally rely on surface-bound or embedded agents that inhibit the growth of bacteria. Common approaches include silver-based compounds, quaternary ammonium salts, and polymer-bound antibacterial additives. These agents can be applied during fiber modification, yarn treatment, or fabric finishing. When integrated at the fiber stage, as is sometimes done with polyester fiber lining, the antibacterial effect tends to show stronger resistance to washing and abrasion compared to surface-only coatings.

Stability of Antibacterial Performance Over Time

The stability of antibacterial treatment depends on how firmly the active substances are fixed within or onto the polyester structure. Treatments that rely on weak physical adhesion may gradually diminish after repeated laundering. In contrast, chemically bonded finishes or melt-blended additives incorporated during fiber production often maintain function for longer periods. Woven lining fabric and knitted lining fabric may show different durability levels because their surface exposure and friction patterns vary during use.

Odor-Resistant Treatment Principles

Odor resistance in polyester textile fabric is closely related to moisture management and bacterial control. Polyester fibers have low moisture absorption, which can contribute to odor retention if not treated. Odor-resistant finishes often work by limiting bacterial growth, neutralizing odor-causing compounds, or improving moisture diffusion across the fabric surface. In dyed lining applications, the compatibility between dyes and odor-resistant agents plays a role in long-term stability.

Interaction Between Odor Resistance and Fabric Structure

The structural form of the fabric influences how odor-resistant treatments perform over time. Knitted lining fabric, with its looped structure, tends to have higher surface area and elasticity, which may accelerate mechanical wear of surface treatments. Woven lining fabric, with a more compact structure, can provide better protection for embedded functional agents. As a result, odor resistance may remain more consistent in tightly constructed fabrics under similar usage conditions.

Anti-Pilling Treatment and Its Functional Basis

Anti-pilling treatment aims to reduce the formation of fiber balls on the fabric surface caused by repeated friction. For polyester textile fabric, pilling is often related to fiber strength and surface smoothness. Anti-pilling finishes may involve resin coatings, surface smoothing treatments, or controlled fiber breakage strategies. These methods limit loose fiber ends from entangling, which helps maintain fabric appearance during long-term use.

Durability of Anti-Pilling Performance

The stability of anti-pilling treatment depends on the balance between surface modification and fabric flexibility. Excessively rigid coatings may reduce pilling initially but can crack or wear off over time. More flexible treatments, especially those compatible with polyester fiber lining, tend to provide more consistent results. Repeated abrasion testing often shows that anti-pilling performance gradually declines, but well-designed treatments can slow this process.

Effect of Washing and Care Conditions

Washing conditions are one of the most significant factors affecting treatment stability. High temperatures, strong detergents, and mechanical agitation can accelerate the loss of antibacterial, odor-resistant, and anti-pilling finishes. Polyester textile fabric finished with chemically bonded agents generally tolerates standard home laundering better than surface-coated fabrics. Dyed lining fabrics may require special attention, as certain detergents can interact with both dyes and functional finishes.

Influence of Dyeing on Functional Treatment Stability

Dyed lining materials introduce additional complexity because dye molecules occupy binding sites on the fiber surface. If functional finishes are applied after dyeing, compatibility between the dye system and treatment chemistry becomes critical. Poor compatibility can lead to uneven performance or faster degradation. When functional agents are introduced before dyeing, they may become more securely fixed within the fiber structure.

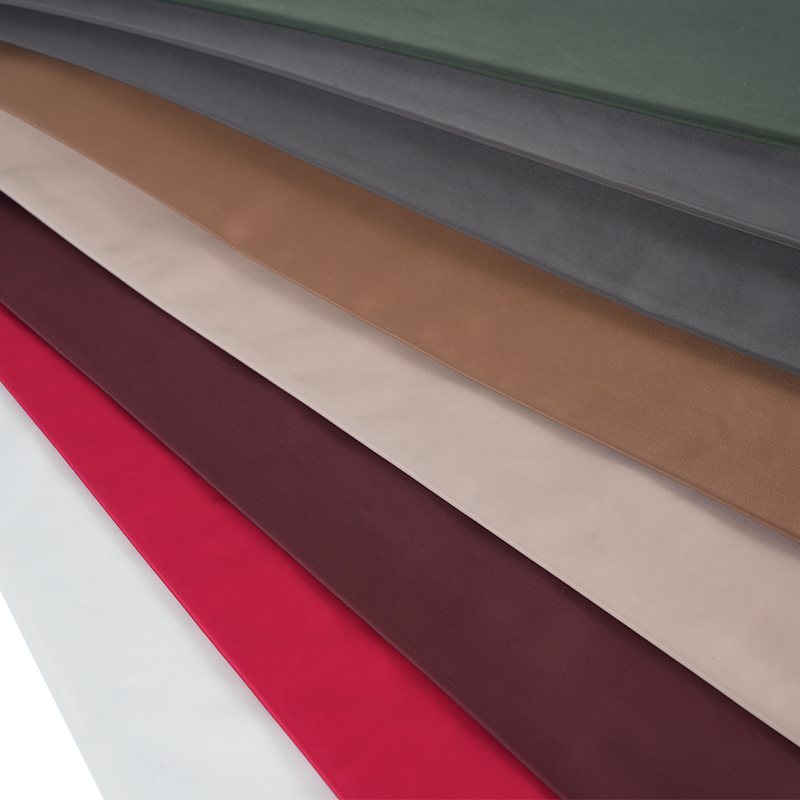

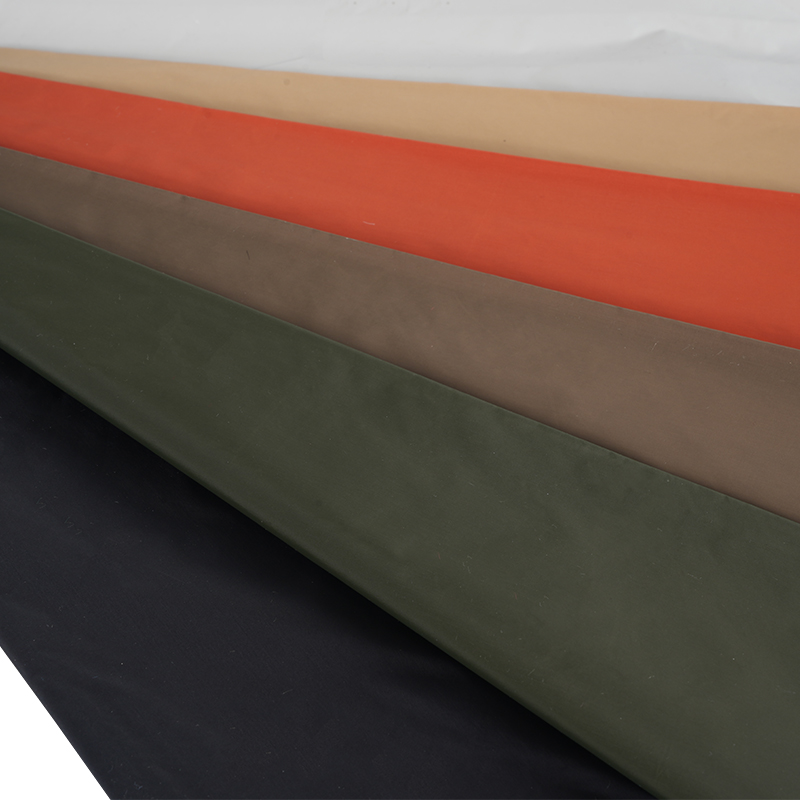

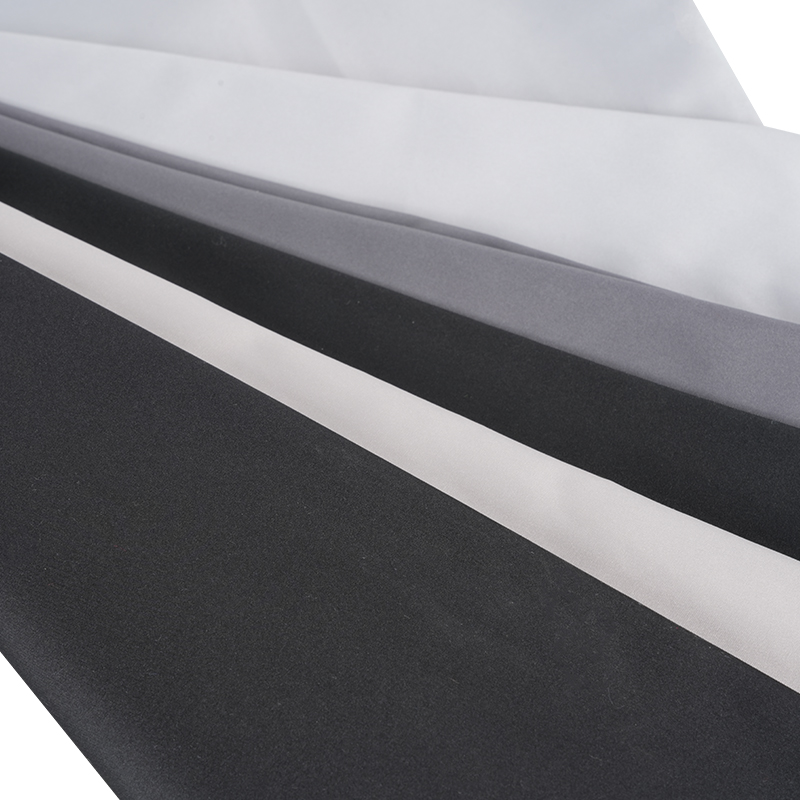

Comparison of Woven and Knitted Lining Fabrics

Woven lining fabric and knitted lining fabric behave differently under mechanical stress. Woven structures typically show lower elongation and more stable surface characteristics, which helps preserve functional finishes. Knitted structures offer flexibility and comfort but experience higher friction during use. As a result, antibacterial and anti-pilling treatments on knitted lining fabric may require reinforcement through fiber-level modification rather than surface-only finishing.

Table: Factors Affecting Treatment Stability

| Factor | Influence on Stability |

| Treatment Method | Chemically bonded or fiber-integrated treatments last longer than surface coatings |

| Fabric Structure | Woven structures protect finishes better than highly elastic knitted structures |

| Washing Conditions | High temperature and strong detergents accelerate performance decline |

| Dye Compatibility | Poor compatibility can reduce functional effectiveness over time |

| Usage Friction | Frequent abrasion reduces anti-pilling and surface-based treatments |

Testing Methods for Evaluating Stability

To assess the stability of antibacterial, odor-resistant, and anti-pilling treatments, standardized laboratory tests are commonly used. Antibacterial effectiveness is measured after multiple wash cycles to observe reduction trends. Odor resistance is evaluated through controlled exposure to odor-causing bacteria or compounds. Anti-pilling performance is tested using abrasion and pilling box methods. These tests provide comparative data rather than absolute performance guarantees.

Long-Term Use Scenarios

In real-world applications, polyester textile fabric is often exposed to a combination of washing, friction, humidity, and body contact. Polyester fiber lining used in garments may undergo frequent laundering, while lining materials in bags or footwear face sustained abrasion. The stability of functional treatments must therefore be evaluated based on specific usage scenarios rather than laboratory results alone.

Role of Manufacturing Control

Consistent manufacturing control plays a key role in ensuring treatment stability. Precise control of temperature, curing time, and chemical concentration during finishing helps improve bonding between functional agents and fibers. For dyed lining and woven lining fabric, uniform application reduces weak points where performance may degrade faster. Quality control testing during production helps identify potential durability issues early.

Environmental and Regulatory Considerations

Stability is also influenced by environmental and regulatory requirements. Some antibacterial agents may be restricted in certain markets, leading manufacturers to adopt alternative solutions with different durability profiles. Eco-focused treatments often prioritize reduced chemical migration, which can improve long-term stability but may offer slower initial performance. Balancing durability with compliance is an ongoing challenge in polyester textile fabric finishing.

Maintenance Practices and User Impact

End-user care practices significantly affect how long functional treatments remain effective. Gentle washing, lower temperatures, and reduced mechanical agitation help preserve antibacterial, odor-resistant, and anti-pilling properties. Clear care labeling for polyester fiber lining and knitted lining fabric helps users maintain expected performance during the product lifecycle.

Integration of Multiple Functional Treatments

When antibacterial, odor-resistant, and anti-pilling treatments are combined, their interaction must be carefully managed. Incompatible chemistries can reduce overall stability. Integrated treatment systems designed specifically for polyester textile fabric often show more consistent performance because they are formulated to work together rather than compete for bonding sites.

Performance Expectations in Practical Applications

While no functional finish remains unchanged indefinitely, stable treatments can maintain acceptable performance throughout the intended service life of the product. Polyester textile fabric with well-designed finishes can provide reliable antibacterial control, reduced odor buildup, and controlled pilling under normal conditions. The key lies in matching treatment technology with fabric structure, dyeing method, and end-use requirements.

English

English 中文简体

中文简体