Cotton fabric sounds simple. Everyone knows it. Everyone uses it. But in real manufacturing, cotton is one of the most discussed materials, and also one of the most misunderstood.

For manufacturers, cotton fabric is not just about softness or comfort. It is about sourcing, consistency, processing behavior, and how the fabric performs after washing, dyeing, cutting, and sewing.

This is why cotton keeps showing up in production meetings, quality reports, and customer feedback.

What Exactly Is Cotton Fabric?

At its core, cotton fabric is made from natural cotton fibers that come from the cotton plant. These fibers are spun into yarn and then woven or knitted into fabric.

That sounds straightforward, but the reality is more complex. Fiber length, fiber strength, spinning method, fabric structure, and finishing processes all change how cotton fabric behaves.

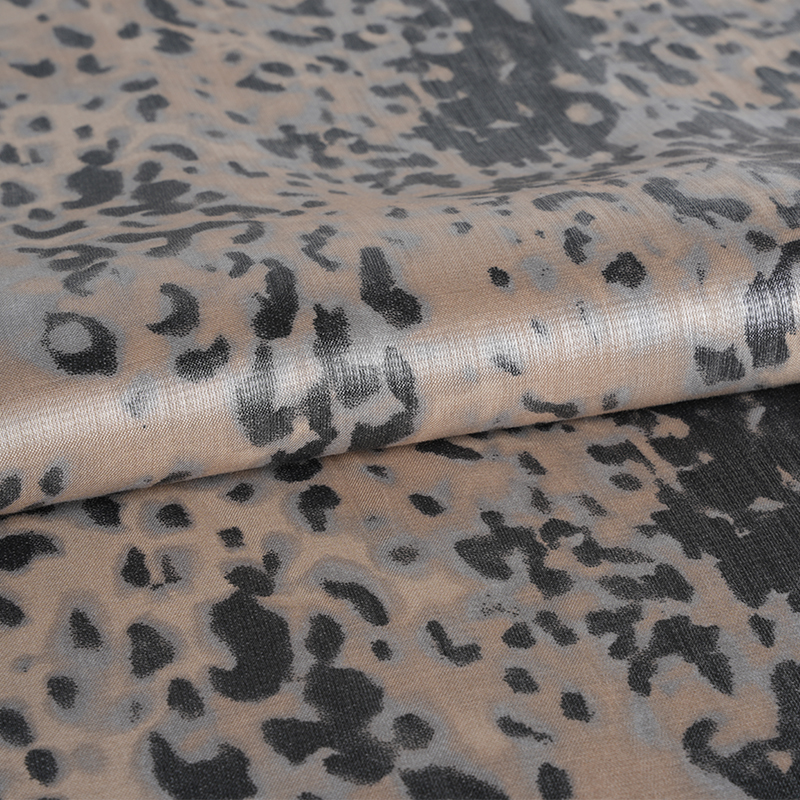

Why Not All Cotton Fabrics Are the Same

Two fabrics can both be labeled as cotton and perform very differently. One may shrink heavily. Another may feel stiff. A third may pill after a few washes.

From a manufacturer's point of view, cotton is a category, not a single product.

Why Is Cotton Fabric So Important for Manufacturers?

Cotton remains one of the most widely used textile materials in the world. Demand is stable across apparel, home textiles, medical supplies, and industrial applications.

Customers trust cotton. They understand it. That trust makes cotton a safer choice for many product lines.

At the same time, cotton sets expectations. Buyers expect breathability, skin-friendliness, and predictable performance. When cotton fabric fails to meet those expectations, complaints come fast.

When Is Cotton Fabric Typically Used?

Cotton fabric shows up in more places than most people realize.

Apparel Manufacturing

T-shirts, shirts, underwear, baby clothing, and casual wear rely heavily on cotton because it feels comfortable against the skin.

Home Textiles

Bedding, sheets, pillowcases, towels, and curtains often use cotton for its moisture absorption and softness.

Medical and Hygiene Products

Cotton is commonly used in bandages, gauze, and hospital textiles due to its breathability and low irritation risk.

Industrial and Promotional Products

Workwear, canvas bags, and promotional textiles often choose cotton for durability and print performance.

How Does Cotton Fabric Actually Work?

The performance of cotton fabric starts at the fiber level.

Fiber Structure

Cotton fibers are hollow and twisted. This structure allows them to absorb moisture easily, which is why cotton feels breathable.

Spinning and Yarn Quality

Longer fibers generally produce smoother and stronger yarns. Short fibers increase fuzz and pilling.

Fabric Construction

Woven cotton fabrics tend to be more stable, while knitted cotton fabrics offer more stretch and softness.

Finishing Processes

Processes like pre-shrinking, enzyme washing, and softening treatments significantly affect final fabric performance.

Common Manufacturing Challenges with Cotton Fabric

Cotton behaves well in many ways, but it is not trouble-free.

Shrinkage

One of the most common complaints. Cotton fibers swell when wet and contract when dry. Without proper finishing, shrinkage is almost guaranteed.

Wrinkling

Cotton wrinkles easily because the fibers lack elasticity. This affects both garment appearance and packaging.

Color Consistency

Cotton absorbs dye well, but uneven fiber quality can cause shade variation.

Pilling and Fuzz

Lower-grade cotton or poor spinning can lead to surface pilling after repeated use.

The Trade-Offs Manufacturers Need to Accept

Choosing cotton fabric always involves compromise.

Advantages of Cotton Fabric

- - Natural and widely accepted material

- - Comfortable and breathable

- - Easy to dye and print

- - Suitable for sensitive skin

Limitations to Consider

- - Shrinks if not properly treated

- - Wrinkles more than synthetic fabrics

- - Drying time is longer

- - Quality varies by source

Manufacturers often blend cotton with other fibers to balance these trade-offs.

Cotton vs Other Common Fabrics

| Fabric Type | Main Strength | Main Limitation |

|---|---|---|

| Cotton | Breathable and comfortable | Shrinkage and wrinkles |

| Polyester | Durable and low shrinkage | Lower breathability |

| Cotton Blend | Balanced performance | Less natural feel |

| Linen | Excellent airflow | High wrinkling |

What Buyers Should Pay Attention To When Sourcing Cotton Fabric

Many sourcing problems start with unclear specifications.

Fiber Length and Grade

Long-staple cotton usually costs more but delivers better surface quality.

Fabric Weight and Density

Lightweight cotton behaves very differently from heavy canvas or twill.

Pre-Treatment Processes

Pre-shrunk and pre-washed fabrics reduce risk in downstream production.

Colorfastness Requirements

End-use matters. Home textiles and garments have different washing standards.

Supply Consistency

Stable quality across batches is often more important than the lowest price.

Why Manufacturers Are Rethinking Cotton Fabric Strategy

Rising labor costs, sustainability pressure, and stricter quality expectations are changing how cotton is sourced and processed.

Many manufacturers now work closely with spinning mills and fabric producers instead of buying spot materials.

Data tracking, lot testing, and standardized finishing are becoming common practices.

Final Thoughts from the Manufacturing Side

Cotton fabric is familiar, but it is not simple.

For manufacturers, success with cotton depends on understanding how it behaves, where it can fail, and what trade-offs are acceptable.

When handled correctly, cotton remains one of the most reliable and versatile textile materials available.

When handled casually, it quickly becomes a source of quality complaints and rework.

In today's manufacturing environment, cotton deserves the same level of attention as any engineered material.

English

English 中文简体

中文简体