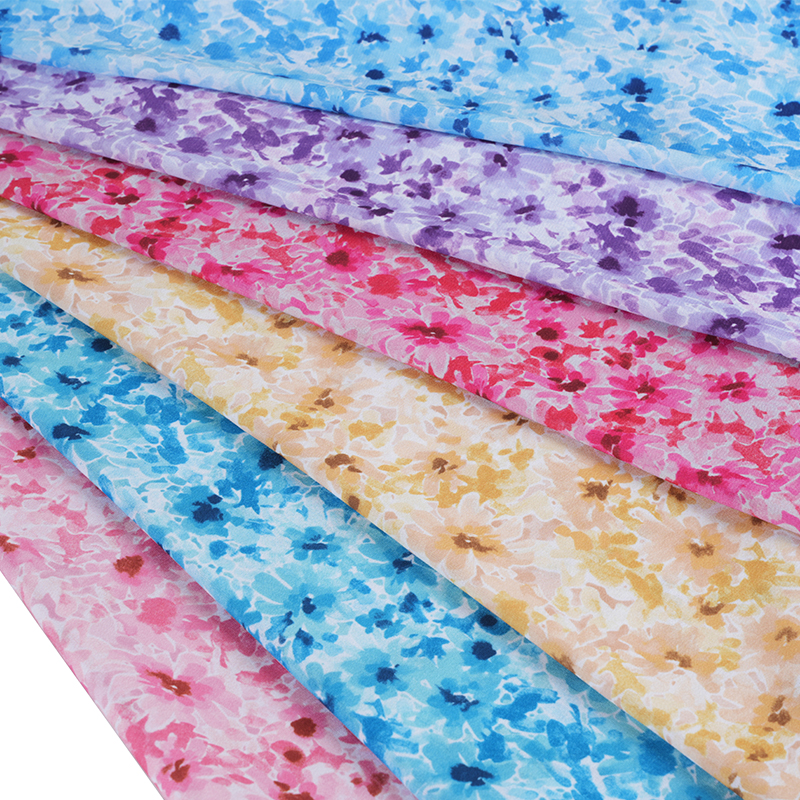

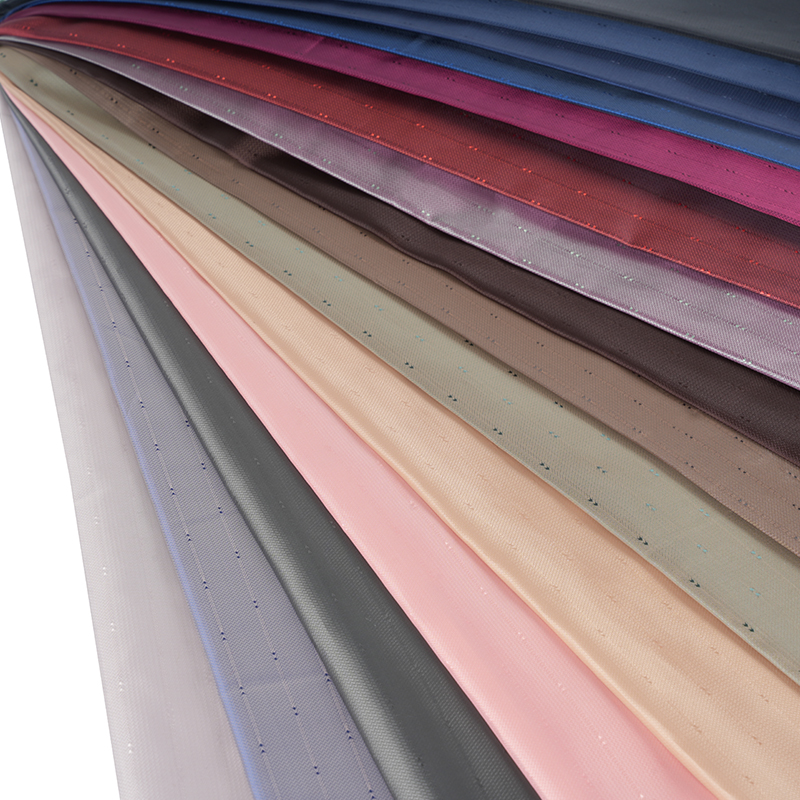

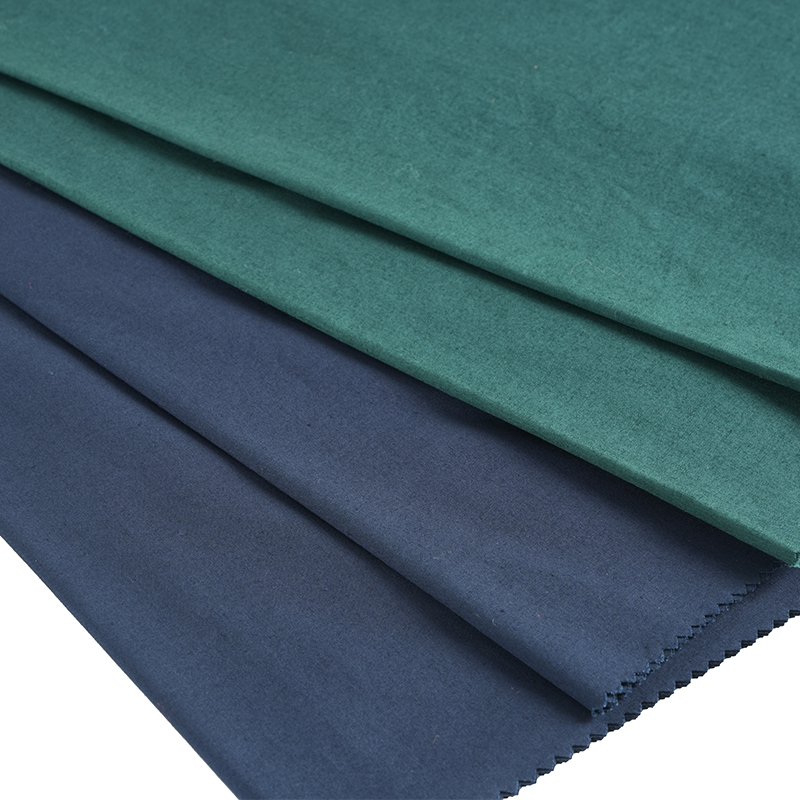

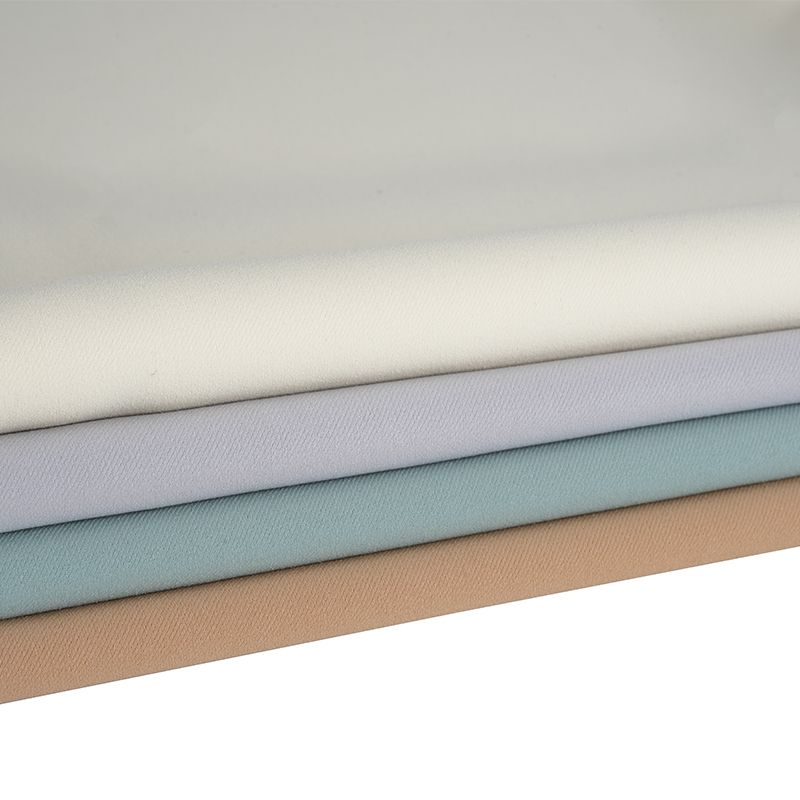

Overview of Sleeve Lining Fabrics and Their Characteristics

Sleeve lining fabrics serve as an inner layer in garments, providing comfort, smoothness, and ease of movement. These fabrics are typically made from polyester, acetate, viscose, or blends, each selected for softness, breathability, and durability. Untreated sleeve lining fabrics, however, are susceptible to shrinkage, fading, and wrinkling during washing, wearing, or exposure to sunlight. Addressing these potential issues requires specific fabric treatments during manufacturing to improve dimensional stability and maintain appearance over time.

The physical and chemical characteristics of the chosen fibers influence how they respond to moisture, heat, and mechanical stress. Polyester, for example, has inherent resistance to shrinking and wrinkling, whereas natural fibers like cotton or viscose may require additional treatment to achieve similar stability. Understanding the properties of the fabric guides the selection of treatments to prevent common performance issues in sleeve linings.

Treatments to Prevent Shrinkage

Shrinkage in sleeve lining fabrics occurs when fibers contract due to moisture, heat, or mechanical action. Pre-shrinking or sanforization processes are commonly used to stabilize the fabric before it is cut and sewn into garments. These processes reduce residual stresses within the fibers and ensure that the lining maintains its intended size after laundering.

Chemical treatments may also be applied to prevent shrinkage. Cross-linking agents or resin finishes can modify fiber structure, providing dimensional stability. For synthetic fabrics, heat setting at controlled temperatures helps lock fiber orientation and further minimizes the risk of shrinkage. These approaches collectively ensure that sleeve lining fabrics retain their original fit and shape throughout the garment's lifecycle.

Treatments to Prevent Fading

Color fading in sleeve lining fabrics is a common concern, particularly when exposed to repeated washing, friction, or ultraviolet light. Dyeing techniques and post-dyeing treatments enhance color fastness, reducing the risk of fading over time. Reactive dyes, vat dyes, and disperse dyes are often chosen based on fiber type to ensure strong fiber-dye bonding.

Additional treatments may include UV absorbers or protective finishes that shield the fabric from sunlight and environmental stressors. These treatments help maintain the visual appeal of the lining and prevent color transfer to outer garments, preserving the overall aesthetic of the clothing.

Treatments to Prevent Wrinkling

Wrinkling occurs when fibers bend or fold and fail to return to their original shape. Sleeve lining fabrics benefit from anti-wrinkle or crease-resistant treatments, which alter the fiber’s surface or internal structure to enhance resilience. Synthetic fibers like polyester may receive heat-setting treatment to fix the fabric in a smooth configuration, while natural fibers may be treated with resin finishes to improve wrinkle recovery.

Anti-wrinkle treatments reduce the need for frequent ironing and maintain a neat appearance even after extended wear or washing. Proper treatment ensures that sleeve linings glide smoothly within sleeves, enhancing garment comfort and functionality while preserving fabric aesthetics.

| Property | Treatment Method | Effect on Sleeve Lining Fabric |

|---|---|---|

| Shrinkage | Sanforization, heat setting, chemical cross-linking | Maintains size stability, prevents post-laundering distortion |

| Fading | UV absorbers, reactive or disperse dyes, protective finishes | Enhances color fastness, reduces color loss over time |

| Wrinkling | Resin finishes, heat setting, anti-crease treatment | Improves wrinkle recovery, keeps fabric smooth and comfortable |

Impact of Fabric Blend on Treatment Effectiveness

The composition of the sleeve lining fabric influences the selection and effectiveness of shrinkage, fading, and wrinkle-resistant treatments. Blends of synthetic and natural fibers may require combined approaches to address the specific behaviors of each component. For instance, a polyester-viscose blend may benefit from heat setting for the synthetic portion and resin finishing for the natural fiber portion, resulting in balanced performance.

Understanding how different fibers respond to temperature, moisture, and chemical treatment helps manufacturers optimize processes. This ensures that sleeve lining fabrics are appropriately treated for long-term dimensional stability, color retention, and surface smoothness.

Testing and Quality Assurance

Quality assurance is critical to verify that sleeve lining fabrics have been successfully treated. Standardized tests assess shrinkage, color fastness, and wrinkle resistance under simulated wear and laundering conditions. Dimensional change measurements after multiple wash cycles indicate the effectiveness of shrinkage treatments. Colorfastness tests under light exposure and rubbing conditions evaluate fading prevention, while wrinkle recovery tests confirm crease resistance.

Testing provides manufacturers and consumers with confidence that the sleeve lining fabrics will maintain performance throughout the intended lifespan of the garment. It also helps identify any treatment inconsistencies before the fabrics are integrated into final products.

Role in Garment Comfort and Functionality

Properly treated sleeve lining fabrics contribute to overall garment comfort and ease of wear. By minimizing shrinkage, the lining retains sleeve shape and fit, reducing restriction during movement. Anti-wrinkle properties ensure smooth gliding of the lining within the sleeve, while colorfast treatments maintain the visual quality and prevent color transfer to outer fabrics. Collectively, these treatments enhance both the functional and aesthetic performance of garments incorporating sleeve linings.

Environmental Considerations of Treatments

Modern textile treatments for shrinkage, fading, and wrinkling increasingly consider environmental impact. Eco-friendly resins, low-impact dyes, and water-efficient finishing processes reduce chemical discharge and energy consumption during manufacturing. Sustainable treatment options allow sleeve lining fabrics to achieve the desired performance without compromising environmental standards, supporting more responsible textile production.

Maintenance and Care of Treated Sleeve Lining Fabrics

Even with shrinkage, fading, and wrinkle-resistant treatments, proper maintenance of sleeve lining fabrics extends their effectiveness. Following recommended washing instructions, avoiding excessive heat during ironing, and limiting prolonged exposure to sunlight help preserve the benefits of the treatments. Routine inspection for signs of wear or fading allows early intervention, ensuring that the fabrics continue to perform as intended over time.

Integration with Outer Garments

Sleeve lining fabrics are integrated with outer garments, and their performance under repeated use depends on both the lining and the surrounding fabrics. Treated sleeve linings reduce friction, maintain shape, and provide a consistent visual appearance, supporting the overall quality of the garment. The choice of compatible lining and outer fabric combinations enhances durability and comfort, particularly in tailored or high-wear clothing where sleeve performance is critical.

Summary of Treatment Benefits

Applying treatments to sleeve lining fabrics to prevent shrinkage, fading, and wrinkling improves dimensional stability, color retention, and surface smoothness. Through pre-shrinking, resin finishing, heat setting, and protective dye treatments, manufacturers ensure that the lining maintains its performance through laundering, wear, and environmental exposure. Testing and quality control confirm treatment effectiveness, while proper care by consumers supports long-term functionality. These treatments collectively contribute to comfort, aesthetics, and longevity of garments that incorporate sleeve linings.

English

English 中文简体

中文简体