What is the Essence and Core Value of Plain Lining?

A. Introduction to Plain Lining

1. Definition and Basic Function

Plain lining refers to a single-colored, pattern-less, or minimally textured layer of fabric used inside garments, bags, curtains, and other textiles. It acts as a "second skin" hidden within the structure.

| Characteristic Parameter | Description | Core Value Embodiment |

|---|---|---|

| Solid Color | A single, neutral color or one that coordinates with the main fabric. | Ensures interior neatness and visual harmony, without interfering with the main fabric. |

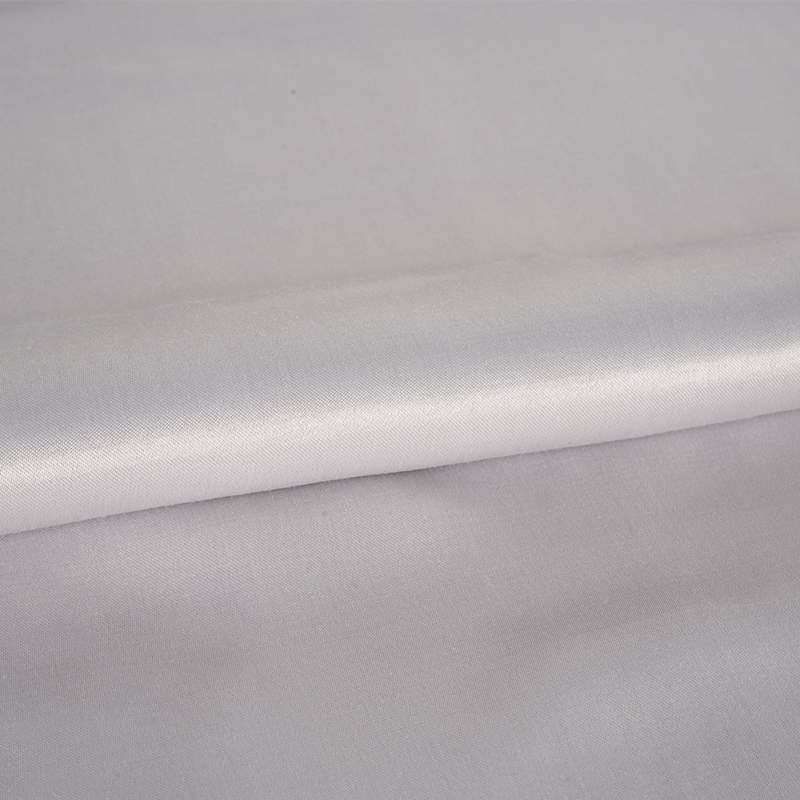

| Smoothness | Low surface friction coefficient, smooth and even to the touch. | Ensures ease of dressing/undressing, reduces friction with undergarments or skin. |

| Lightweight | Generally low fabric weight (e.g., 40-80 GSM). | Does not burden the main fabric or add bulk, maintaining light drape. |

| Durability | Possesses high tear and abrasion resistance. | Extends the lifespan of the entire finished product, resisting internal wear from daily use. |

2. Core Functions of Plain Lining in Garment Structure

The value of plain lining lies in its multiple functions that collectively enhance overall quality and user experience:

- Enhancing Wearing Comfort: Plain lining acts as a buffer between the skin and potentially rough or irritating main fabrics (like wool or coarse linen). Its smooth touch resolves issues of skin discomfort.

- Protecting the Main Fabric: The lining isolates the main fabric fibers from body perspiration, oils, and external dirt. For delicate fabrics like silk or cashmere, it is an effective internal protective barrier.

- Finishing the Product: Plain lining successfully conceals internal seam allowances, interlining edges, and structural details. A garment only demonstrates high-caliber craftsmanship if its interior is equally neat and smooth.

- Optimizing Drape: A plain lining with appropriate weight and drape can "guide" the movement of the main fabric. In suits or dresses, the lining adds weight, ensuring the garment hangs naturally and maintains structural stability and shape.

3. Historical Evolution and Modern Development of Plain Lining

The application of plain lining has a long history. Before the development of the modern textile industry, natural fibers like silk and linen were the primary lining materials, offering unparalleled comfort but at a high cost.

| Historical Period | Main Plain Lining Materials | Key Characteristics |

|---|---|---|

| Traditional Period | Silk, Fine Linen | Extremely high comfort, natural breathability, high cost, complex care. |

| Industrial Period | Acetate, Rayon (Viscose) | Silk-like luster and hand-feel, moderate cost, allowing lining to be mass-applied. |

| Modern Development | Polyester, Cupro (Bemberg), Regenerated Fibers | Excellent durability, low cost, functional properties (anti-static, quick-dry), environmental sustainability. |

The modern trend in plain lining is toward functional and high-performance properties, such as water-repellent plain lining for outdoor wear, and anti-static or antibacterial plain lining for everyday garments.

4. How Plain Lining Improves Garment Durability and Appearance

Plain lining is crucial for the long-term value of a garment:

- Structural Support: For complexly cut items (like suit sleeves and jacket shoulders), plain lining provides a stable, non-stretching inner layer, preventing the main fabric from suffering permanent deformation or loosening during wear and activity.

- Anti-Transparency: Many fashion fabrics, especially light-colored or sheer chiffons and silks, have a degree of transparency. Plain lining provides an opaque barrier without adding excessive weight, ensuring the wearer's privacy and the garment's modesty.

- Reducing Internal Stress: The lining absorbs most of the internal friction generated when dressing/undressing or moving. This effectively protects the main fabric's fiber structure, significantly extending the overall lifespan of the garment.

What are the Types, Classifications, and Application Fields of Plain Lining?

The diversity of plain lining is the basis for its widespread application. Selecting the appropriate plain lining material and type is a core step in garment design and production, based on the main fabric characteristics, garment use, and budget.

A. Types of Plain Lining Fabrics

Plain lining materials are primarily classified by fiber source, with each type offering unique performance and value to the garment:

1. Natural Fiber Plain Lining

Natural fibers are known for their excellent comfort and breathability, but their cost and care difficulty are generally higher.

- Silk: Considered the "gold standard" in plain lining. It has a natural luster, excellent skin-friendliness, and breathability. Silk plain lining is suitable for haute couture, evening gowns, and delicate women's suits, offering unparalleled luxury and fluid movement.

- Cotton: Often used in garments requiring high moisture absorption and structural stability. Cotton plain lining is breathable but less smooth than synthetics, primarily used for casual jackets or linings requiring sweat absorption.

- Rayon/Cupro: Strictly speaking, these are regenerated cellulose fibers, falling between natural and synthetic materials. Cupro (Bemberg) is highly regarded for its "breathable fiber" properties, smooth hand-feel, and excellent drape, and it naturally possesses anti-static properties. It is often used in high-end suits and jackets as a premium alternative to silk plain lining.

2. Synthetic Fiber Plain Lining

Synthetic fibers dominate the plain lining market due to their superior durability, low cost, and ease of care.

- Polyester: The most common and widely used plain lining material. Its advantages include high strength, strong wrinkle resistance, easy cleaning, and low cost. However, its disadvantages are poor breathability and moisture absorption, and it is prone to generating static electricity.

- Acetate: Has a silk-like luster and good drape. It is softer than polyester and often used in traditional suits and coats, but has low wet strength and is sensitive to heat, requiring extra caution during ironing.

| Plain Lining Core Material Performance Comparison | Hand-feel/Smoothness | Breathability/Absorbency | Durability (Abrasion) | Cost Level | Primary Functional Positioning |

|---|---|---|---|---|---|

| Silk | Excellent/Slippery | Excellent/High | Fair | Highest | Luxury, Comfort, Lightweight |

| Cupro | Excellent/Slippery | Excellent/High | Good | Medium-High | Premium Comfort, Anti-static |

| Polyester | Good/Slippery | Poor/Low | Excellent | Low | Durable, Anti-wrinkle, Low Cost |

| Acetate | Good/Slippery | Average/Medium | Fair | Medium | Drape, Luster |

3. Functional and Blended Plain Lining

To meet specific wearing demands, many plain linings adopt functional treatments or blending techniques:

- Stretchy Plain Lining: Typically blended with spandex/elastane, giving the lining elasticity. This is crucial for sportswear, slim-fit trousers, or any outerwear requiring high freedom of movement, ensuring the plain lining stretches in sync with the main fabric.

- Anti-static Plain Lining: Targeted at synthetic fiber plain linings, solving the issue of garments clinging to the body and attracting dust in dry, cold seasons, via conductive yarns or chemical finishing agents.

- Insulated Plain Lining: The reverse side of the lining is lightly brushed, or a thin layer of wool/polyester filling is sewn onto the lining, used in winter coats or jackets to increase warmth.

4. The Trend and Choice of Sustainable Plain Lining

With increasing industry focus on sustainability, eco-friendly plain lining is becoming mainstream:

- Regenerated Cellulose Fibers (e.g., TENCEL™ Lyocell): These plain linings are derived from sustainably managed wood pulp, with minimal environmental impact during production. They offer excellent softness, moisture absorption, and breathability.

- Recycled Polyester Plain Lining: Made from recycled plastic bottles and other materials, effectively reducing reliance on virgin petroleum resources. It maintains the excellent durability of polyester plain lining while significantly lowering the environmental footprint.

B. Application Scope of Plain Lining

The application of plain lining extends far beyond traditional clothing, playing both a functional and aesthetic role in various textile fields.

1. Apparel Sector

- Coats and Jackets: Plain lining is an important component for structural support, temperature regulation, and wind resistance. It allows inner clothing to be put on and taken off smoothly, preventing fabric snagging.

- Dresses and Skirts: Enhances the drape and fluidity of the skirt, ensuring smooth movement and necessary privacy (anti-transparency).

- Trousers: Reduces friction between the main fabric (such as wool or coarse twill) and the skin, especially in the knee and hip areas, significantly improving wearing comfort.

2. Accessories and Luggage Sector

- Handbags and Backpacks: Plain lining protects internal items from external friction and hard object damage, while stabilizing the structure of internal pockets and compartments, helping the bag maintain its shape under load.

- Wallets and Small Leather Goods: Enhances the internal feel and user experience of leather goods, protecting stored cards and cash from staining or damage by the leather material.

3. Home Furnishings Sector

- Curtains: As a backing, plain lining provides additional blackout (with thicker linings) and insulation functions. It adds weight to the curtain, making it hang more fully and drape more orderly.

- Cushions and Pillows: Plain lining is used to prevent internal fillings (down, foam, or cotton batting) from escaping and helps the external decorative fabric maintain a flat shape.

4. Importance of Plain Lining in Custom Clothing

In the high-end and custom sector, plain lining elevates from a purely functional component to a design detail:

- Embodying Custom Details: Tailors and designers can showcase the garment's uniqueness and inner quality by choosing contrasting plain lining colors or intricate quilting patterns.

- Exclusive Identification: Although the plain lining remains solid-colored, embroidering the wearer's name, initials, or the custom date on the inside of the lining becomes the exclusive signature detail of the custom garment.

How to Select Plain Lining? And What are the Necessary Sewing Practices?

Correct plain lining selection and appropriate sewing techniques are the two core pillars determining garment quality and durability. Incorrect matching or crude craftsmanship can severely diminish the final product's value.

A. How to Choose the Right Plain Lining

The correct plain lining selection is a multi-dimensional decision process involving function, aesthetics, and practicality.

1. Matching Main Fabric Characteristics

Plain lining must be highly compatible with the main fabric in terms of performance to avoid mismatched deformation after wearing or washing.

| Matching Characteristic | Core Requirement | Consequences of Incorrect Selection |

|---|---|---|

| Weight and Thickness | Plain lining weight should not exceed 75% of the main fabric weight. It must remain light to avoid a heavy, droopy feel. | Lining too heavy: Causes the main fabric to sag, wrinkle, and lose its light feel. |

| Drape and Fluidity | Both must be dynamically consistent. If the main fabric is crisp, the plain lining should also be slightly stiff; if the main fabric is soft and flowing, the plain lining must be smooth and fluid. | Inconsistent drape: Causes garment twisting, "lining shifting," or the lining "sticking" to the main fabric. |

| Shrinkage Rate and Washing Requirements | The plain lining's shrinkage rate must be the same as or lower than the main fabric's. Their care labels must also be compatible. | Inconsistent shrinkage: Lining shrinks after washing, causing the garment interior to be tight and deformed, and external wrinkles to appear. |

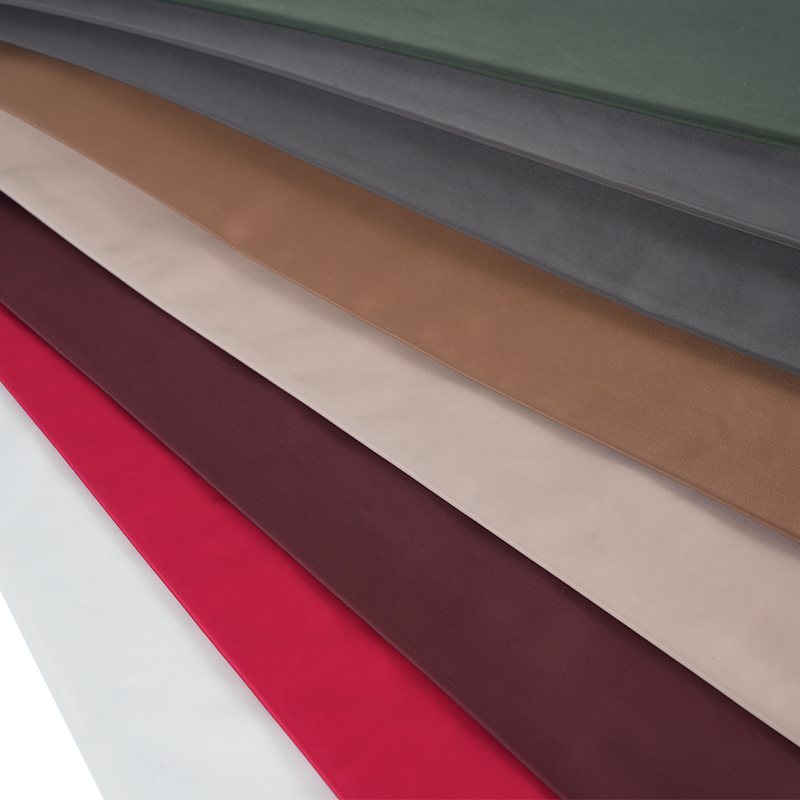

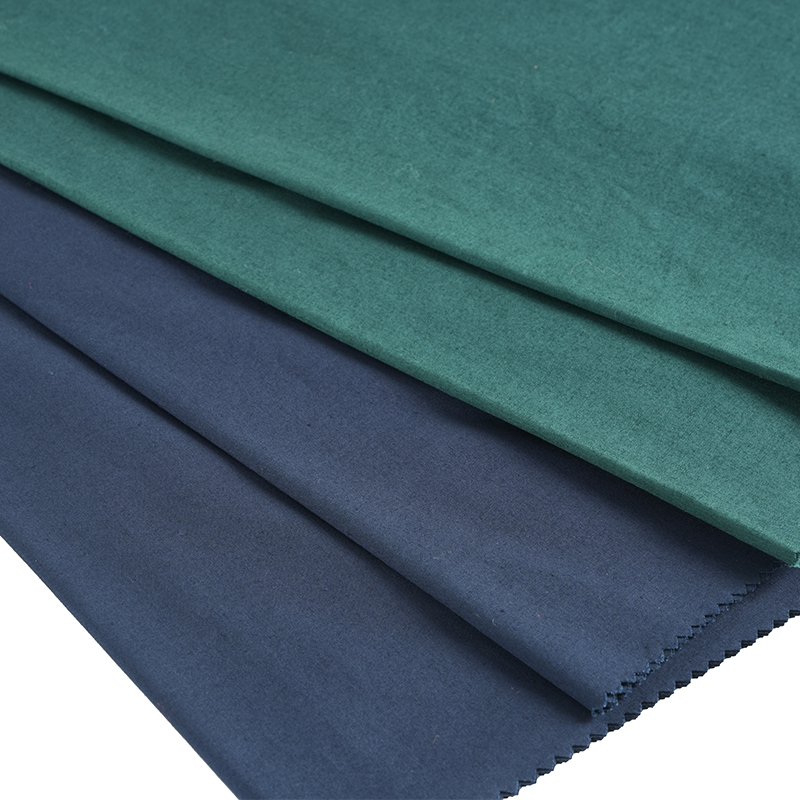

2. Principles for Plain Lining Color, Luster, and Hand-feel Matching

While hidden inside, the aesthetic choice of plain lining affects the wearer's psychological comfort and the garment's overall premium feel.

- Color Selection:

- Classic Neutral Plain Lining: Black, navy, grey, and beige are versatile options suitable for most main fabrics.

- Analogous Color Plain Lining: Choose a lining color with the same hue as the main fabric but a slightly different value, creating internal visual harmony.

- Contrast Color Plain Lining Philosophy: In high-end customization, bold contrast colors (like a deep red plain lining with a black wool coat) are a design statement, highlighting the attention to internal detail, but require the lining material itself to be high quality.

- Luster:

- High Luster Plain Lining: Such as silk or high-luster acetate, suitable for evening wear and silk dresses, enhancing the sense of luxury.

- Matte Plain Lining: Such as cupro or matte polyester, suitable for wool suits and casual jackets, avoiding excessive reflection to maintain a composed texture.

- Hand-feel Matching: The plain lining's hand-feel must meet the standard of being skin-friendly, especially for garments worn with fewer layers underneath. A soft, smooth touch is key to enhancing the wearing experience.

3. Selecting Functional Plain Lining Based on Use

| End Use | Functional Plain Lining Requirement | Recommended Material Examples |

|---|---|---|

| Summer Apparel/Sportswear | Ultimate breathability and moisture-wicking properties. | Cupro, Lyocell, porous structure polyester. |

| Slim-fit Jackets/Trousers | Needs stretch to accommodate movement, anti-friction. | Spandex-blended plain lining, high-smoothness plain lining. |

| Winter Coats/Trench Coats | Extra warmth, wind resistance, anti-static function. | Quilted plain lining, brushed polyester, carbon fiber blend plain lining. |

| Sheer Dresses/Chiffon | Must have sufficient grip to prevent the main fabric from sliding or bunching up against the lining. | Lightweight acetate, micro-denier polyester. |

4. Cost-Benefit Analysis: The Long-Term Value of Quality Plain Lining

Although plain lining accounts for a small proportion of the total cost, its quality determines the long-term value of the garment. High-quality plain lining (like Cupro), while having a higher initial cost than ordinary polyester, significantly extends the garment's lifespan and boosts user satisfaction due to its excellent breathability, anti-static properties, and durability, ultimately offering a higher return on value.

B. Plain Lining Sewing: Skills and Techniques

Sewing plain lining demands high precision. Due to the fabric often being thin, slippery, and sensitive to needle holes, special techniques are required.

1. Plain Lining Cutting Preparation and Anti-Slip Treatment

- Using Sharp Tools: Professional sharpened scissors or a rotary cutter must be used for precise cutting. Blunt tools will snag plain lining fibers, causing edge deformation, especially with slippery polyester or acetate plain linings.

- Pinning Techniques: The slipperiness of plain lining is the main sewing challenge.

- Fine Pinning: Use a large number of ultra-fine, round-headed pins to secure the lining, minimizing visible needle holes.

- Spray Adhesive/Weights: Use temporary (removable) spray adhesive on the cutting table or use heavy weights and professional fabric press plates to ensure the plain lining does not shift during cutting.

- Ease Allowance: When cutting plain lining, especially in high-movement areas like the back and armholes, a slight ease allowance (typically 0.5cm-1cm) must be left compared to the main fabric. This ensures the lining won't tear or restrict movement when the wearer moves, a critical detail in professional garment construction.

2. Sewing Machine Setup and Plain Lining Seaming Techniques

- Needle and Tension Adjustment:

- Use Fine Needles: It is recommended to use 60/8 or 70/10 fine needles, or Microtex needles, to minimize damage to plain lining fibers.

- Reduce Tension: Appropriately reduce the sewing machine's thread tension and use a shorter stitch length (e.g., 2.0mm-2.5mm) to prevent the plain lining from developing a "wavy" or puckered appearance.

- Seam Allowance Treatment: Plain lining seam allowances must be neat, durable, and smooth.

- Plain Seam: The most commonly used basic seam.

- French Seam: Used for sheer or light plain linings (like silk), which completely encloses the seam allowance inside, providing the smoothest and most durable edge finish.

- Bound Seam: In high-end suits, decorative materials (like bias binding) are used to bind the plain lining's edges, enhancing internal aesthetics and structural durability.

3. Bagged and Full Lining Sewing Methods

- "Bagged" Full Lining Process: This is the most common industrial plain lining process. The plain lining is first sewn into an "inner bag" similar to the outer garment, then sewn to the outer garment's edges (like the neckline, front opening, hem) right sides together. The whole garment is then turned out through a gap left in the lining. Finally, the opening is closed by hand or machine stitching.

- Bound Lining in High-End Suits: In unlined or half-lined suits, plain lining covers only specific areas (like sleeves, shoulders). The remaining internal seam allowances are finished with exquisite binding or overlocking, maintaining a lightweight feel while ensuring internal neatness.

4. Professional Plain Lining Industrial Sewing Flow

In garment mass production, plain lining sewing efficiency and quality control are paramount.

- Automated Cutting: Computer-controlled cutting tables are used for precise cutting, minimizing errors in the plain lining fabric.

- Specialized Equipment: Industrial sewing machines with differential feed mechanisms are used to prevent the plain lining from being stretched or puckered during sewing.

- Quality Inspection: Plain lining seams undergo stretch testing and visual inspection to ensure no puckering, no wrinkles, and precise dimensional matching with the main fabric.

IV. How to Properly Maintain Plain Lining Items? And How to Solve Common Problems?

The long-term performance of plain lining depends not only on its initial material and sewing craftsmanship but also on daily maintenance and care. Furthermore, understanding and resolving common failures encountered during the use and production of plain lining is crucial for ensuring the garment's lasting appeal.

A. Care and Maintenance of Plain Lining Items

The core principle for caring for lined items is to adhere to the care requirements of the most delicate component between the main fabric and the plain lining.

1. Cleaning Guide for Different Plain Lining Materials

When cleaning, the plain lining's fiber characteristics must be distinguished to select the most appropriate method.

| Plain Lining Material Type | Recommended Cleaning Method | Key Considerations |

|---|---|---|

| Synthetic Fibers (Polyester, Nylon) | Machine wash (gentle cycle, cold water), low heat tumble dry or hang dry. | Avoid high temperatures, which can cause the plain lining to shrink or melt. |

| Natural Fibers (Cotton) | Machine wash (neutral detergent, warm water), avoid excessive spinning. | Prone to wrinkling, needs ironing when slightly damp, check color fastness. |

| Regenerated Cellulose (Cupro, Rayon) | Preferably dry clean or hand wash (cold water), do not wring. | Low wet strength, prone to deformation when washed; lay flat or hang dry. |

| Animal Fibers (Silk) | Dry clean only or professional hand wash (silk-specific detergent). | Avoid direct sunlight, do not use bleach. |

2. Ironing and Storage Precautions for Plain Lining Items

Correct ironing and storage methods can maximize the preservation of the plain lining's smoothness and shape.

- Plain Lining Ironing:

- Low-Temperature Principle: All plain linings, especially synthetic fibers, must be ironed using low or medium-low temperature (usually one or two dots), preferably with a press cloth.

- Avoid Excessive Pressure: Ironing movements should be gentle, avoiding prolonged pauses on seams to prevent leaving iron marks or "shine" on the main fabric.

- Hanging Storage for Lined Garments:

- Wide-Shoulder Hangers: For coats and suits, use wide-shoulder wooden hangers to support the garment's shoulder structure and the plain lining's weight, preventing deformation under gravity.

- Ensure Space: Ensure lined garments have enough space in the wardrobe, avoiding compression, which can cause permanent creases in the plain lining.

3. Secrets to Extending Plain Lining Lifespan

- Avoid Excessive Friction: When wearing, avoid carrying heavy, rough backpacks for long periods, which causes concentrated wear on the plain lining in the shoulder and back areas.

- Regularly Check Wear Areas: Pay special attention to high-friction areas like the underarms, cuffs, and hem. If minor damage is found, professional repair should be done promptly to prevent holes from enlarging.

- Ventilation and Drying: After wearing, garments should be hung in a ventilated area to allow sweat and moisture to fully evaporate before storage. Moisture is a primary cause of plain lining fiber degradation and odor generation.

B. Common Problems and Solutions in Plain Lining Production and Use

When dealing with plain lining, common issues affecting appearance and function may arise. Knowing how to resolve these is key to the garment's lasting appeal.

1. Problem: Plain Lining Wrinkling, Puckering ("Lining Shifting")

Refers to irregular waves or puckers appearing inside the plain lining, affecting the smoothness of the external fabric.

- Cause of Failure: Mismatch in shrinkage rate or cutting size between the plain lining and the main fabric, or the plain lining was excessively stretched during the sewing process.

- Solution:

- Fabric Balancing: The plain lining must undergo sufficient pre-shrinking treatment before cutting.

- Adding Ease: Consciously leave a small amount of ease (usually 0.5cm to 1cm) for the plain lining in high-movement areas (like the center back, elbow). This allows the lining to accommodate stretch during movement and reduces wrinkles when still.

- Professional Securing: Use "spot tacking" or professional fixed-point stitching to secure the plain lining to the main fabric's internal structure points (like shoulder seams, hem, side seams), maintaining its stable position without compromising drape.

2. Problem: Plain Lining Loosening or Shrinkage

Loosening usually occurs after prolonged wear, while shrinkage often occurs after improper washing.

- Cause of Failure:

- Loosening: Plain lining materials (like some rayons) undergo irreversible stretching in humid environments or after prolonged hanging.

- Shrinkage: Plain lining material has poor heat resistance or was washed/dried at high temperatures without pre-shrinking treatment.

- Solution:

- Preventive Pre-shrinking: All plain linings must undergo pre-shrinking treatment consistent with the finished product's care requirements before sewing.

- Restoration Treatment (for shrinkage): For mildly shrunk plain lining, a steam iron can be used for simultaneous stretching and steaming, attempting to restore its original size, but this requires extreme caution to prevent damage.

- Reinforcing Plain Lining: Use fusible reinforcement strips on the plain lining's edges (like the hem) to prevent loosening in high-stretch areas.

3. Problem: Plain Lining Mismatch, Leading to "Twisting" or "Poor Fit"

This is the most serious problem, usually caused by a conflict between the plain lining's drape or weight and the main fabric.

- Cause of Failure: The main fabric is crisp but the plain lining is too soft and thin, unable to "guide" the main fabric, leading to arbitrary twisting; or the plain lining is too slippery, causing inner clothing to slide inside, resulting in a very poor wearing experience.

- Solution:

- Re-evaluate Fabric Matching: At the initial design stage, professional testing must ensure the plain lining's density, weight, and drape are within a harmonious range with the main fabric.

- Precise Dimensions: Ensure all plain lining dimensions and seam placements align precisely with the main fabric's internal structure, avoiding internal stress caused by dimensional deviation.

- Adjusting Plain Lining Smoothness: If the plain lining is too smooth, causing the garment to slip off, consider using a functional plain lining with a slight grip or anti-slip finish.

V. What are the Professional FAQs and Technical Standards for Plain Lining?

This chapter delves into the most common questions users have about plain lining, analyzes the professional textile testing standards used to measure its quality and performance, and touches upon its hidden aesthetic value and psychological impact.

A. Plain Lining User Focus Points Q&A (FAQs)

1. What is the difference between Plain Lining and Interlining/Interfacing?

This is a common point of confusion in textile applications. Both are inside the garment, but their functions and application areas are completely different.

| Comparison Item | Plain Lining | Interlining/Interfacing |

|---|---|---|

| Primary Function | Enhance comfort, protect main fabric, beautify the interior, optimize drape. | Shape, support, increase crispness, maintain edge shape (e.g., collar, cuff). |

| Application Area | Covers the entire interior of the garment (e.g., body, sleeves, skirt). | Local application, such as collars, cuffs, plackets, waistbands, pocket edges. |

| Hand-feel/Characteristics | Smooth, soft, good drape. | Rough or with adhesive (fusible interfacing), stiff, no drape requirement. |

Functional Contrast: The goal of plain lining is to create a comfortable and neat internal environment; the goal of interlining is to shape and stabilize specific structures of the garment.

2. How to quickly identify Plain Lining material?

In the absence of a professional label, the material can be quickly assessed through sensory evaluation and simple tests.

- Hand-feel and Touch:

- Silk/Cupro: Smooth, fine, soft touch, naturally cool to the touch.

- Polyester/Acetate: Polyester feels slightly stiffer, with a slight "rustling" sound when rubbed; acetate is softer than polyester but less skin-friendly than natural fibers.

- Luster and Drape:

- High Luster: Silk, acetate, and certain high-quality polyesters have a distinct sheen.

- Matte: Cotton, cupro (Bemberg), and recycled polyester usually have a soft matte effect and a more natural drape.

- Burn Test (Controlled Environment Only): The most accurate but destructive test.

- Natural Fibers (e.g., Cotton, Silk): Burns quickly, smells like burning hair or paper, leaves soft ash.

- Synthetic Fibers (e.g., Polyester): Melts and drips when burned, emits a plastic odor, forms a hard bead.

3. Does Plain Lining need pre-washing?

Absolutely necessary. Natural fibers (like cotton, rayon) and some synthetic fibers have a degree of shrinkage. If the lining is not treated with water or steam before sewing, it may shrink after the first wash while the main fabric remains unchanged. This leads to the garment interior tightening, puckering, and the overall shape twisting, severely impacting wear and appearance.

4. Can Plain Lining color be completely different from the main fabric?

Design Consideration: Yes, this is a popular and bold design trend.

- Uniform Design: Plain lining usually chooses colors in the same hue as the main fabric or classic neutrals (black, grey, navy) to maintain internal harmony and understatement.

- Contrast Design: Using bold contrasting colors for the plain lining (e.g., deep red, bright green, or a patterned lining with a dark coat) is a way to showcase the garment's inner quality and personalized detail. This design is often used in high-end customization, trendy outerwear, or designer pieces, aiming to create a "surprise" effect. Designers must ensure the contrasting plain lining has extremely high color fastness to prevent color transfer or bleed onto the main fabric due to friction or moisture.

B. Plain Lining Quality Control and Performance Testing

Professional plain lining must pass stringent textile performance tests to ensure its functionality and durability.

1. Plain Lining Abrasion Resistance Testing

As plain lining is inside the garment, it is constantly subjected to friction between the lining and inner clothing, and the lining and the body. Therefore, abrasion resistance is one of its most critical quality indicators.

- Martindale Abrasion Test: Simulates the friction of daily wear, assessing durability by the number of cycles the lining withstands under standard pressure. For coat or suit plain lining, typically 15,000 to 20,000 cycles are considered acceptable.

- Wyzenbeek Abrasion Test: Another commonly used abrasion test method, particularly for assessing the durability of upholstery and curtain plain linings.

2. Plain Lining Color Fastness and Anti-Fading Properties

The plain lining's color must be stable and reliable, not transferring or fading due to external environments or internal factors (like sweat).

- Crocking Color Fastness (Dry/Wet): Tests whether the plain lining color will transfer onto a white standard cloth due to friction in dry or wet conditions. This indicator is crucial for contrasting plain linings.

- Perspiration Color Fastness: Simulates the effect of human sweat (alkaline and acidic) on the plain lining color. If color fastness is poor, the plain lining may discolor or transfer color to inner clothing in areas like the underarm.

- Light Color Fastness: Evaluates the plain lining's (e.g., curtain lining) ability to resist fading when exposed to light. Usually measured using the Blue Wool Scale.

3. Plain Lining Tear Strength and Seam Slippage Testing

These tests ensure the plain lining remains intact and stable when subjected to external tension.

- Tear Strength: Measures the plain lining's resistance to tearing. As plain lining is typically thin, insufficient tear strength can lead to the garment tearing at seams when dressing forcefully or moving.

- Seam Slippage Test: Measures whether the plain lining's threads will slip out of the seam edge when subjected to tension. Slippage causes seam openings, one of the most common failures of low-quality plain lining.

C. Aesthetic and Psychological Impact of Plain Lining

Plain lining is not purely functional; it directly influences the perceived value of the garment and the wearer's psychological comfort.

1. Impact of Plain Lining Color on Perceived Garment Value

- Visual Contrast Design of Inner and Outer Fabric: Using bold, saturated plain lining colors can significantly elevate the perceived value of the garment. This contrast implies the designer's attention to internal detail, suggesting the exquisite craftsmanship of custom or high-end ready-to-wear.

- Psychological Effect: A bright plain lining provides a momentary pleasure ("inner luxury") when the wearer puts on or takes off the garment. This hidden color detail is part of the user experience.

2. Contribution of Plain Lining Hand-feel to Wearing Experience

The plain lining's hand-feel is a quantifiable indicator of its "skin-friendliness."

- Softness: Affects the comfort level when the plain lining contacts the skin. Cupro and silk have high softness due to the natural structure of their fibers.

- Slipperiness (Friction Coefficient): This is key to determining the ease of dressing/undressing. A high-slipperiness plain lining (like quality polyester taffeta) minimizes clinging and friction with innerwear.

3. Plain Lining and Ergonomics

The design of plain lining must follow ergonomic principles during vigorous activity or movement.

- Reducing Friction: High-smoothness plain lining reduces the heat and irritation generated by internal friction, preventing skin chafing.

- Contribution to Body Comfort: In the back and underarm areas, highly breathable plain lining (like Cupro) effectively manages humidity and heat, keeping the areas dry. Furthermore, precisely cut plain lining ease ensures the lining will not pull the main fabric or restrict movement in any posture, thereby guaranteeing maximum comfort during dynamic activity.

VI. Practical Applications and Deep Outlook of Plain Lining

This chapter aims to discuss practical application cases of plain lining in different garment types, analyze its core technical role in high-end customization, and look forward to how future textile technology will revolutionize the function and performance of plain lining.

A. Classic Plain Lining Application Case Analysis

The application method of plain lining is not fixed but is finely tuned according to the garment's structure, purpose, and seasonal needs.

1. Plain Lining Structure of High-End Suits

In high-end suit making, plain lining not only affects wearing comfort but is also a core factor determining the suit's shape and weight. There are three main plain lining structures:

| Suit Plain Lining Structure | Plain Lining Coverage Area | Core Plain Lining Material Requirement | Main Functional Advantage |

|---|---|---|---|

| Full Lining | 95% (Almost completely covered except for internal structures) | Cupro, High-density Acetate (High smoothness, anti-static) | Optimal shaping, warmth, internal protection. Provides the most formal, solid shape and drape, suitable for autumn/winter or business occasions. |

| Half Lining | 30% - 40% (Mainly covers sleeves, upper back, front chest) | Cupro, Lightweight Polyester (Lightweight, high breathability) | Balance of structural support and breathability. Retains support in key areas while reducing weight, better suited for spring/autumn wear. |

| Unlined | < 10% (Only sleeves or necessary structure points) | Ultra-lightweight Cupro (Extremely light, high breathability) | Ultimate lightness, maximum breathability. Suitable for summer casual suits, requires extremely high craftsmanship for the main fabric and internal stitching. |

2. Winter Coat Plain Lining

In winter coats, plain lining must meet the dual demands of warmth and wind resistance.

- Quilted Plain Lining Combined with Insulation: The quilting process secures the plain lining with a thin layer of insulation filling (such as polyester fiber or light down), forming an integrated warmth layer. This plain lining structure effectively prevents filling shifting while providing a smooth inner surface for easy dressing/undressing.

- Functional Plain Lining: Using plain lining materials with wind-resistant or thermal-reflective coatings can significantly improve the coat's warmth efficiency without adding excessive bulk.

3. Summer Silk Dress Plain Lining

Summer garments require plain lining that is light, thin, and breathable.

- Selecting Ultra-lightweight Plain Lining: Using ultra-fine denier polyester or silk plain lining in the 40-50 GSM range.

- Balancing Anti-Transparency and Breathability: The main function of plain lining is to provide anti-transparency, but it must ensure its breathability is no less than the main fabric to avoid stuffiness. Cupro is an ideal choice for summer silk or chiffon dress plain lining due to its unique moisture-wicking and breathability properties.

B. Role of Plain Lining Technology in High-End Customization

In high-end customization, plain lining has moved beyond utility to become a measure of craftsmanship and an embodiment of brand philosophy.

1. Plain Lining Customized Colors and Exclusive Identification

- Customized Colors: Custom clients can usually choose from hundreds of plain lining colors and materials to match the main fabric. This internal personalization choice is one of the core values of high-end customization, upgrading functional plain lining to a design element expressing individuality.

- Exclusive Identification: Although the plain lining remains solid-colored, embroidering the client's name, initials, or the custom date on the inside of the lining (such as the inner pocket or center back) becomes the "inner signature" of a custom garment.

2. Plain Lining Combined with Hand-Stitching Techniques: Slip Stitch and Securing Skills

In top-tier custom garments, the connection between the plain lining and the main fabric does not rely solely on machine stitching.

- Slip Stitch: This is a nearly invisible hand-stitching technique used to connect the plain lining's edges (like cuffs, hem turn-ups) to the main fabric. It ensures a smooth, seamless connection of the plain lining, a hallmark of exquisite hand-craftsmanship.

- Floating Plain Lining: The lining in high-end suits is usually not completely fixed at the hem but is left with a certain ease or fixed only at a few points, allowing it to move independently of the main fabric, ensuring maximum freedom of movement and drape.

3. Plain Lining's Supportive Role as the Garment's "Soul"

Plain lining is responsible for enveloping and protecting the garment's internal framework. The tension, smoothness, and drape of quality plain lining are precisely calculated to complement the main fabric's characteristics, ensuring the garment maintains the initially designed perfect shape during both the wearer's dynamic and static states. It is dubbed the "second skeleton" of the garment's shape.

C. Future Impact of Textile Technology on Plain Lining

With continuous advancements in material science and smart technology, the function of plain lining is evolving from a simple inner layer to a high-performance, multifunctional module.

1. Application of Ultra-thin, High-Strength Fibers in Plain Lining

Future plain linings will use less material to achieve higher performance standards.

- Micro-denier Fiber Technology: Developing fibers that are thinner, smoother, and stronger than current plain linings, such as ultra-fine nylon or liquid crystal polymer (LCP) fibers. These can provide excellent abrasion and tear resistance while maintaining a "sensory-free" experience.

- Enhanced Strength: Boosting the plain lining's tear resistance, especially in sportswear and outdoor gear, allowing the plain lining to withstand greater internal stress without tearing.

2. Development of Antibacterial and Self-Cleaning Functions in Plain Lining

Treating plain lining as a hygienic and functional active layer.

- Antibacterial Plain Lining: Embedding silver ions or special mineral particles in the fibers to achieve permanent antibacterial and anti-odor functions, particularly suitable for undergarments and sportswear.

- Self-Cleaning Technology: Incorporating nanotechnology or photocatalytic technology, enabling the plain lining to decompose sweat and dirt, reducing washing frequency, extending the garment's lifespan, and maintaining internal cleanliness.

English

English 中文简体

中文简体