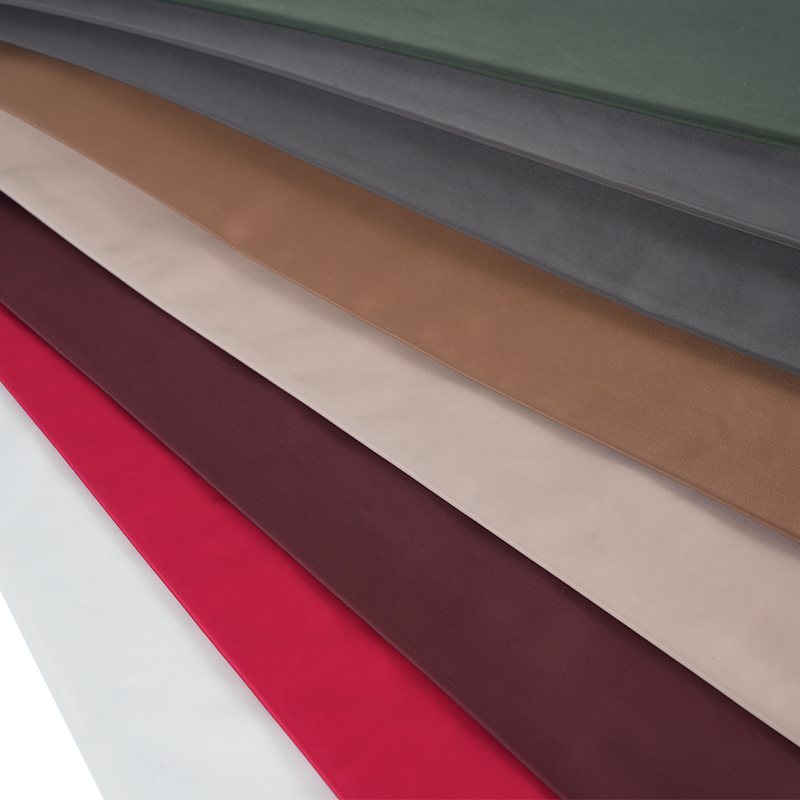

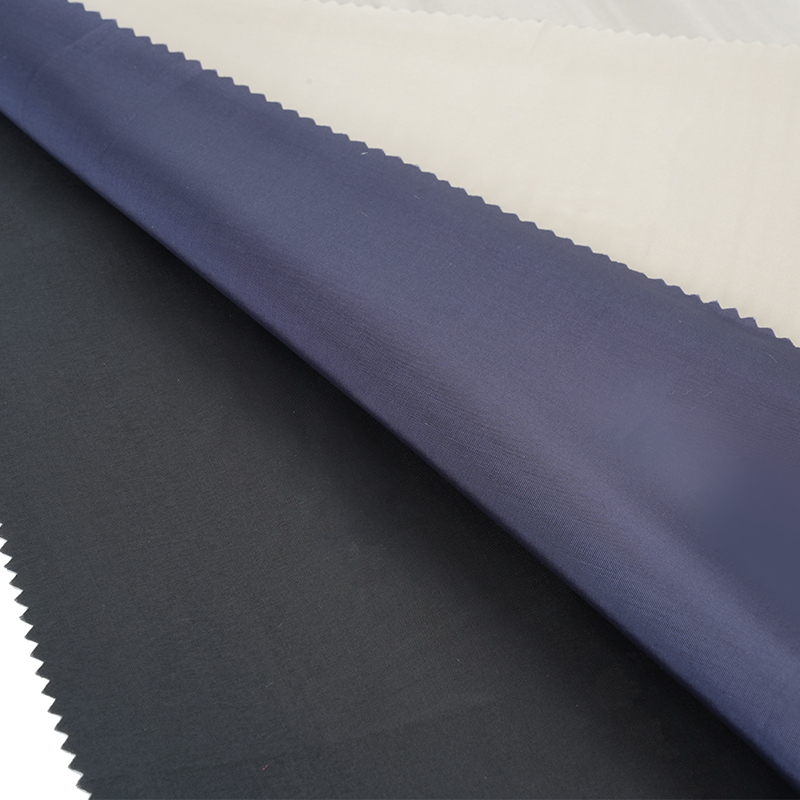

Introduction to Woven Lining Fabrics

Woven lining fabrics are commonly used in various textile applications, including clothing, upholstery, and accessories. These fabrics are known for their durability and ability to withstand wear and tear. The structure of woven fabrics, created by interlacing yarns in a criss-cross pattern, provides strength and stability. This characteristic makes woven lining fabrics suitable for areas that experience friction, such as the inner lining of garments and bags. However, the ability of woven lining fabrics to endure the friction and wear of daily use depends on several factors, including the type of fibers used, the weave pattern, and the overall construction of the fabric.

Friction and Wear Resistance in Woven Fabrics

Friction and wear resistance are key qualities in any fabric that will undergo repeated use. When a fabric is subjected to friction, the surface fibers can begin to break down, leading to pilling, abrasion, or even tearing. Woven lining fabrics, with their tight interlacing of threads, are often better equipped to resist these issues compared to other fabric types. However, not all woven fabrics are created equal. The strength of the yarns used, the tightness of the weave, and the finish applied to the fabric all contribute to its ability to withstand friction over time. Fabrics made from natural fibers, such as cotton, may have lower abrasion resistance than synthetic fibers like polyester or nylon, which are often chosen for their enhanced durability.

Factors Affecting the Durability of Woven Lining Fabrics

Several factors affect the durability of woven lining fabrics, particularly their ability to withstand friction and wear. These factors include the type of fiber used, the yarn twist, the weave pattern, and the weight of the fabric. Stronger fibers, such as nylon or polyester, typically provide better resistance to wear and friction. Additionally, fabrics with a higher yarn twist and a tighter weave tend to offer greater strength and durability. The weight of the fabric also plays a role—heavier fabrics generally have more fibers per unit area, which can improve their resistance to abrasion. Finally, the finish applied to the fabric, such as a protective coating, can enhance its wear resistance by creating a barrier between the fabric and abrasive surfaces.

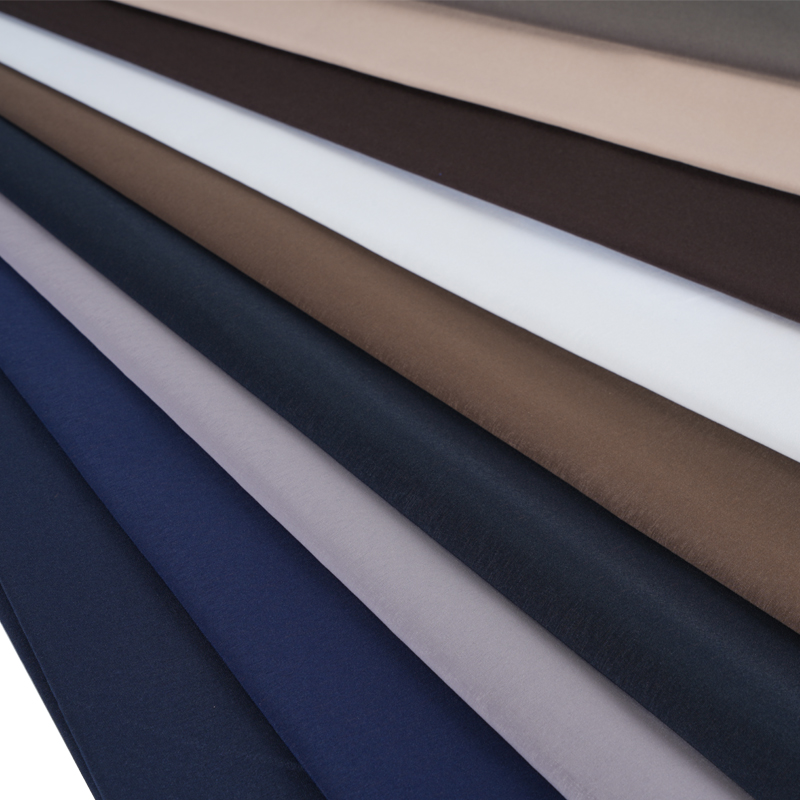

Comparison of Woven and Knitted Lining Fabrics

Woven fabrics are often compared to knitted lining fabrics in terms of their durability and performance. While woven fabrics are strong and stable, knitted fabrics, which are made by interlocking loops of yarn, have a stretchier, more flexible nature. This makes knitted fabrics more comfortable in certain applications, but it also means they may not offer the same level of friction resistance as woven fabrics. Woven lining fabrics generally perform better in terms of durability, as their rigid structure helps them resist abrasion and wear. However, knitted fabrics have their own advantages, such as better drape and comfort, which can be more suitable for certain uses, such as in garments that require more flexibility and movement. A comparison of these two types of lining fabrics can be helpful in understanding which material is more appropriate for specific applications.

Woven Lining Fabrics and Their Applications

Woven lining fabrics are used in a variety of applications that require durability and strength. One of the most common uses of woven lining fabrics is in the interior linings of jackets, trousers, and coats. These fabrics are also frequently used for bag linings, upholstery, and even in certain industrial applications. Their strength allows them to withstand the wear and tear caused by daily use, particularly in areas where friction is common, such as the inside of a coat sleeve or the lining of a handbag. In automotive and furniture upholstery, woven lining fabrics provide a long-lasting barrier against friction and wear, contributing to the longevity of these items. Additionally, woven fabrics are often used in protective clothing, such as work uniforms or safety gear, where durability and resistance to friction are paramount.

Material Durability Comparison Table

| Fabric Type | Friction Resistance | Comfort | Durability | Applications |

|---|---|---|---|---|

| Woven Lining Fabric (Polyester/Nylon) | High | Moderate | High | Heavy-duty applications (bags, work uniforms) |

| Knitted Lining Fabric | Moderate | High | Moderate | Activewear, t-shirts, casual wear |

| Woven Lining Fabric (Cotton) | Moderate | High | Moderate | Less demanding applications (garments, upholstery) |

Maintenance of Woven Lining Fabrics

Maintaining woven lining fabrics is essential for ensuring their longevity and continued performance in high-friction areas. Regular cleaning and proper care can help maintain the fabric’s strength and resistance to wear. For example, it is important to follow the manufacturer’s instructions regarding washing and drying, as excessive heat or harsh detergents can weaken the fibers. Additionally, repairing small areas of damage, such as loose threads or minor tears, can prevent further wear and extend the fabric's life. Fabric protectors, such as sprays or coatings designed to enhance abrasion resistance, can also be applied to woven fabrics to provide an added layer of protection against friction and wear.

Performance Under Different Conditions

The performance of woven lining fabrics under various conditions can vary depending on the specific requirements of the application. In environments where high levels of friction are expected, such as in work uniforms or heavy-duty bags, woven fabrics made from synthetic fibers like polyester or nylon are often preferred due to their superior abrasion resistance. On the other hand, woven fabrics made from natural fibers like cotton may be more appropriate for less demanding applications, where comfort and breathability are prioritized over durability. The fabric’s ability to withstand environmental factors, such as moisture, UV exposure, or extreme temperatures, can also influence its performance. For example, polyester and nylon fabrics are generally more resistant to moisture and UV degradation than cotton fabrics.

Testing Friction Resistance of Woven Lining Fabrics

To assess the friction and wear resistance of woven lining fabrics, various testing methods are employed. The Martindale Abrasion Test is one of the most common methods used to measure the durability of fabrics when exposed to friction. This test involves rubbing a fabric sample against a standardized abrasive surface under controlled conditions to simulate wear and tear over time. The number of rubs a fabric can withstand before showing signs of damage is recorded, providing a clear indication of its abrasion resistance. Another common test is the Taber Abraser Test, which similarly assesses how a fabric performs under friction but with a rotating abrasive wheel. Both of these tests provide valuable data for manufacturers and consumers, helping to determine the appropriate fabric for specific applications.

Wear and Tear Over Time

Over time, woven lining fabrics that are exposed to constant friction will inevitably experience some level of wear. The extent of this wear depends on several factors, including the type of fabric, the intensity of friction, and the environmental conditions. Fabrics made from synthetic fibers such as polyester and nylon generally exhibit a longer lifespan when exposed to frequent friction compared to natural fibers like cotton or wool. However, even synthetic fabrics will eventually show signs of wear, such as pilling, thinning, or fraying, especially in high-contact areas. While woven fabrics are generally more resistant to wear than other fabric types, regular maintenance and proper care can help prolong their useful life.

Impact of Fiber Type on Friction Resistance

The type of fiber used in woven lining fabrics plays a significant role in their ability to withstand friction and wear. Synthetic fibers, such as polyester, nylon, and aramid, are commonly used for their enhanced durability and abrasion resistance. These fibers are more resistant to wear and tear than natural fibers like cotton and wool, which are more prone to fraying and breaking under constant friction. Polyester, for example, is known for its high tensile strength and resistance to abrasion, making it an ideal choice for applications that require high-performance fabrics. On the other hand, natural fibers like cotton, while softer and more breathable, do not have the same level of durability and may show signs of wear more quickly under heavy use.

Applications of Knitted Lining Fabrics

Knitted lining fabrics, while generally more flexible and comfortable than woven fabrics, may not always provide the same level of abrasion resistance. The structure of knitted fabrics allows them to stretch and conform to the body, making them ideal for applications where comfort and fit are important. However, in high-friction areas, knitted fabrics may be more susceptible to damage, especially when made from lighter-weight fibers. Knitted lining fabrics are commonly used in clothing such as t-shirts, sweaters, and activewear, where flexibility and comfort are prioritized over durability. For more demanding applications that require enhanced resistance to friction, woven fabrics are often the preferred choice due to their higher tensile strength and abrasion resistance.

English

English 中文简体

中文简体